Demands as the basis for production recommendations result from material requirements planning processes. In the Production recommendations application, you can view and edit the generated production recommendations and generate production orders from them.

Availability of the Production recommendations application depends on the setting of the Production method function in the Customizing application under Production. If the production method is deactivated there, two alternative fields Bill of material and Routing are available instead of the Production method field.

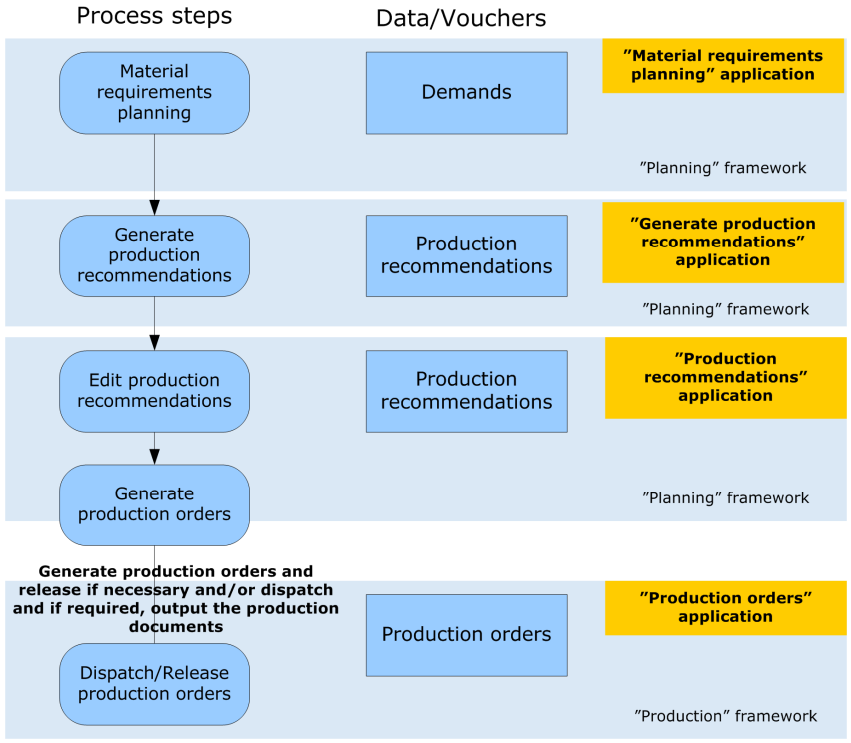

Processes

Before the actual production process begins, the user can have the system calculate the demand for production items with the help of material requirements planning. Production recommendations can be generated for further processing from the determined quantity in the Generating production recommendations application. Next, they can be edited in the Production recommendations application.

A production recommendation is a recommendation for producing certain quantity of a certain item at a specific time point. The production quantity is the quantity of the item to be produced.

The user can discard production recommendations by deleting them or generating production orders from them. They are processed in the Production recommendations application.

Detailed information can be found in the Material requirements planning and Generate production recommendations articles.

Business processes for production recommendations and the subsequent relationships with other applications and business entities have been described below:

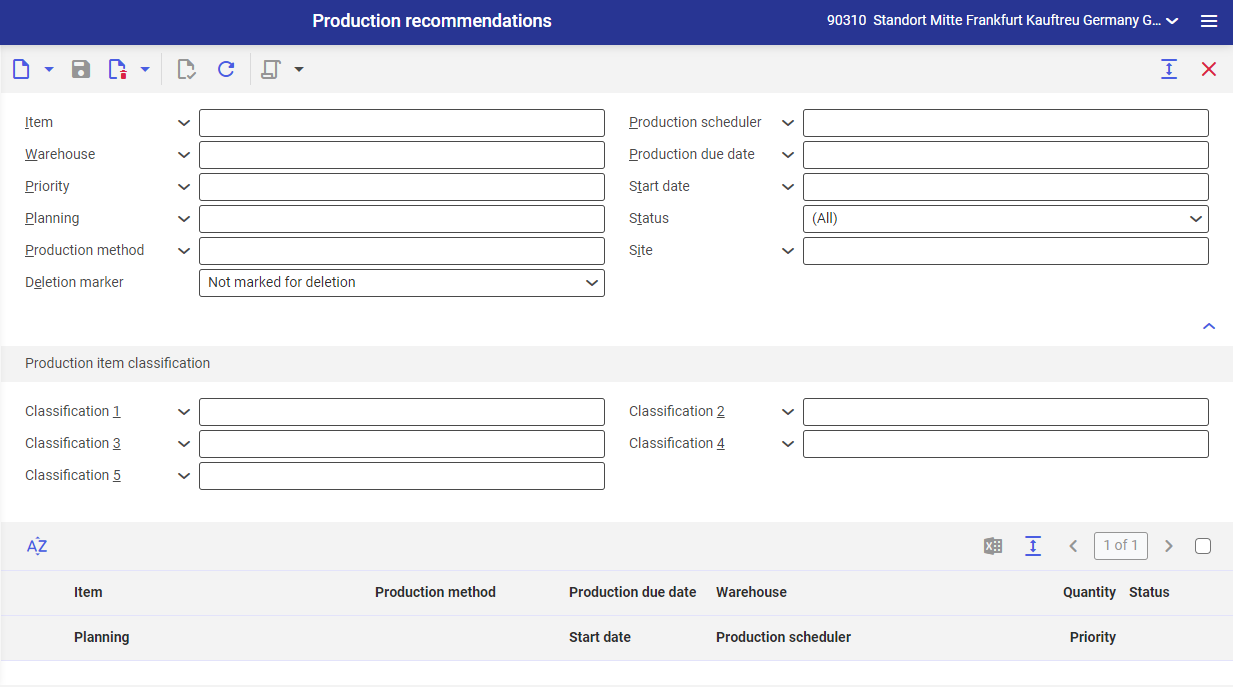

The Production recommendations application is composed of:

- Query pane – used to specify the search criteria for production recommendation

- Work pane – lists and, if necessary, further processes the query results

Query pane

Following buttons are available in the query pane, next to the standard buttons:

- [Add] – creates a new query to display selected production recommendations

- [Select action] → [Generate production orders] – once you select this action, production orders are generated from the checked production recommendations. To do so, first you need to select the production recommendations in the work pane, for which production orders will be generated. Effects of this action are as follows:

- the system includes all selected production recommendations and generates production orders from them

- a production order is generated for each production recommendation

- the user selects a relevant voucher type in a dialog window

- other data for the production order are accepted as defaults from other areas, for instance from the production order type or the item master data from the Items application

- after the generation of the production orders, the corresponding production recommendations are automatically deleted from the system. This is to ensure that multiple orders are not generated accidentally from a production recommendation.

- [Select action] → [Generate and release production orders] – once you select this action, production orders are generated from the checked production recommendations. They are also released in the same step. The production order can further be processed in the Production orders application.

- [Select action] → [Generate and dispatch production orders] – once you select this action, production orders are generated from the checked production recommendations. They are also dispatched in the same step. The production order can further be processed in the Production orders application.

- [Select action] → [Generate, dispatch, and release production orders] – once you select this action, production orders are generated from the checked production recommendations. They are also dispatched and released in the same step. The production order can further be processed in the Production orders application.

- [Select action] → [Generate, dispatch, release, and print production orders] – once you select this action, production orders are generated from the checked production recommendations. They are also dispatched, released, and printed in the same step. The production order can further be processed in the Production orders application.

- [Select action] → [Process] – when you select this action, all marked production recommendations are assigned the In process status. By changing the status, it is possible to distinguish the recommendations that the production scheduler is currently working on, for instance. In addition, recommendations with this status can be included in the material requirements planning. The status has an informational role.

- [Select action] → [Release] – when you select this action, all marked production recommendations are assigned the Released status. The status has an informational role.

- [Select action] → [Block] – when you select this action, all marked production recommendations are assigned the Blocked status. The status has an informational role.

The user can specify different search criteria in the query pane to limit the search in order to display specific production recommendations. All search criteria are optional, i.e. they can be entered if needed. Fields available in the query pane:

- Item – select one or more items as search criteria. All existing items for which production, inventory or purchasing data has been created (in the Items application under the Production, Inventory Management or Purchaing views) are permitted.

- Production scheduler – select a production scheduler who created the production recommendations as search criteria.

- Warehouse – select a warehouse with which production recommendations are associated as a search criterion.

- Production due date – enter a production due date for which production recommendations will be displayed. This due date is calculated as part of planning before production recommendations are generated.

- Priority – select a priority number as a search criterion; it is rertieved from the category of the generated production order.

- Start date – enter a production start date for which production recommendations will be displayed. This start date is calculated as part of planning before production recommendations are generated.

- Planning – select a planning run according to which production recommendations have been generated.

- Status – use the status of a production recommendation as a search criterion. The following statuses can be selected:

- Created

- In process

- Released

- Blocked

Status can be assigned via a relevant action in the Production recommendations application.

- Production method – select a production method for which production recommendations will be displayed. This field is not available if production methods are deactivated in the Customizing application under the Production function.

- Bill of material – select a bill of material for which production recommendations will be displayed. This field is available if production methods are deactivated in the Customizing application under the Production function.

- Routing – select a routing for which production recommendations will be displayed. This field is available if production methods are deactivated in the Customizing application under the Production function.

- Site – select one or more sites for which production recommendations will be displayed. The search is then applicable to all warehouses of the selected sites.

- Deletion marker – select production recommendations on the basis of the deletion marker (deletion flag). Available options include:

- All

- Marked as deleted

- Not marked for deletion

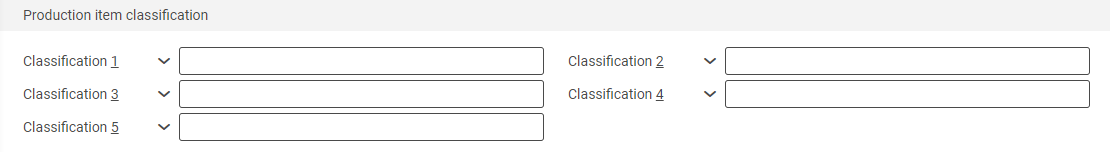

You can also unhide the Product item classification grouping with the [Show/hide] button, where production recommendations can additionally be filtered according to the defined classifications.

- Classification 1-5 – enter a production item classification 1-5 as a search criterion. Classifications are defined in the Classifications application.

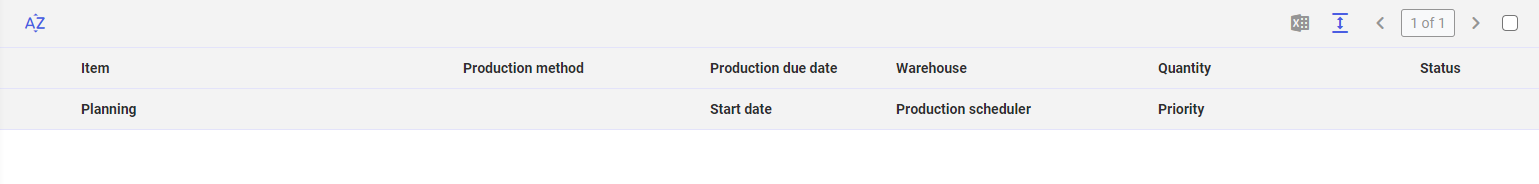

Work pane

Production recommendation data that the system finds on the basis of the search criteria entered in the query pane is displayed in the work pane.

For each production recommendation, the following data is displayed in the table:

- Item – name of the item for which a production recommendation has been generated

- Planning – material requirements planning from which the production recommendation was generated

- Production method – the production recommendation for which the production recommendation was generated. It can be edited. The production method is defined for a product in the Items application under the Production view, but it is retrieved from the pending material requirements planning.

- Bill of material – the bill of material for which the production recommendation was generated. This field is available if production method is deactivated in the Customizing application under the Production function.

- Routing – the routing for which a production recommendation was generated. This field is available if production methods are deactivated in the Customizing application under the Production function.

- Production due date – the production date determined as part of planning is displayed and can be edited. This due date is calculated as part of planning during generation of production recommendations.

- Start date – the start date determined as part of planning is displayed and can be edited. The start date is calculated as part of planning during generation of production recommendations.

- Warehouse – the receipt warehouse for production recommendations. It can be edited.

- Production scheduler – the employee responsible for a production recommendation and for generating a production order from this recommendation. It can be edited.

- Quantity – the production quantity determined as part of planning is displayed and can be edited.

- Priority – specifies the priority of production recommendations. It can be edited.

- Status – the status of the production recommendation is displayed. Available values include:

- Created

- In process

- Released

- Blocked

- Checkbox – activate the checkbox and thus the production recommendations for further processing. Use the meta checkbox for checking all boxes.

Business entities

The following business entity is relevant to the Production recommendations application: com.cisag.app.production.obj.ProductionRequirement. It is used, for instance, to:

- assign authorizations

- set up activity definitions

- import or export data

The business entity is part of the following business entity group: com.cisag.app.production.OrderData.

Authorizations

Authorizations can be assigned by means of authorization roles, as well as by assigning an organization. The authorization concept is described in the Authorizations article.

Authorizations for business partners

The Production recommendations application is not released for business partners.