Creating a new production order manually

A new production order can be added manually. For this purpose, you need to complete and save the mandatory fields in the query pane.

Procedures:

- Open Production orders application.

- Select a production order type in the Number field.

- Select the [New] button on the standard toolbar to create a new production order.

- The system will generate a production order of the specified type. The order number is assigned automatically according to the number range defined in the production order type.

- Complete Production item field in General tab.

- Select the [Validate] button to verify the fields.

- Finally, save the new order with the [Save] button.

- To automatically get data to the line item table from the bill of resources or the bill of material and the routing, select the button [Select action] → [Execute].

Creating a new production order from an existing production order

Using the [Reuse object names] button under [New] you can generate a new production order to which data from another, existing order will be copied. This way, there is no need to enter again the data.

Procedures:

- Open Production orders application.

- Open the production order to be duplicated.

- Select [Reuse object names] button in the toolbar to duplicate the current production order.

- The system will generate a production order of the specified type. The order number is assigned automatically according to the numbering scheme defined in the production order type.

- Finally, you can save the new production order.

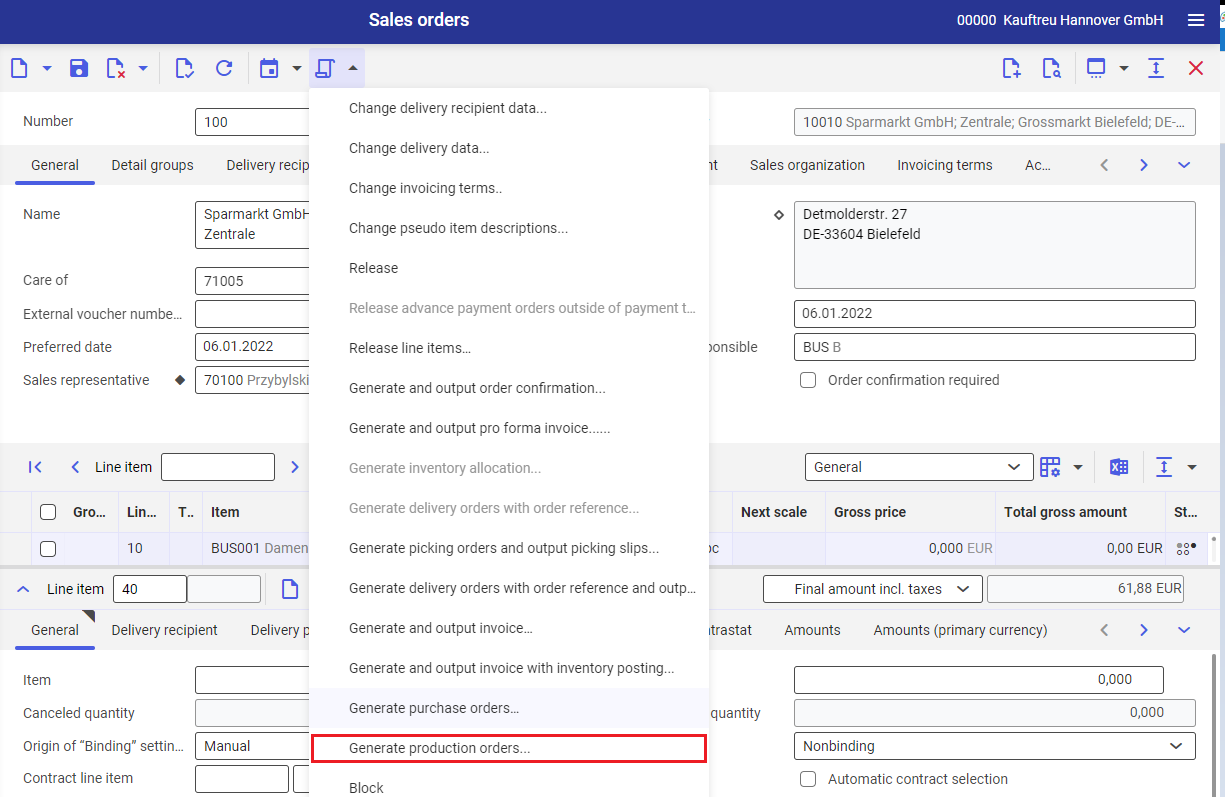

Creating a new production order from a sales order

A production order can be generated from an existing sales order.

This way, the relevant data is copied from the sales order line item

and completed in the production order query pane.

More information on how to generate a production order from a sales order can be found in the article Sales orders.

Creating a new production recommendation from a production order

Production recommendations are usually generated based on material requirements planning. A recommendation type is determined during its generation, thus there is no need to complete the fields manually. During generation you can begin further recommendation processing steps, such as execution.