Topic overview

The following article describes the Inventory Management view of the Items application. This view is used to define settings for items managed in a warehouse.

Other views have been described in separate articles. General functions of the Items application that refer to several or all views have been described in the Items article.

More information on other views may also be found in the article Procedures: Items.

Definition of terms

Alternative item

Several alternative items can be assigned to each item. An alternative item is an item that can be used as an alternative if the item wanted is not available. For example, the alternative item has the same or similar attributes (with minor differences).

Substitute item

A substitute item is an independent item that is created as a unique successor for an item. It is used if the actual item is no longer included in the inventory because it can no longer be purchased or produced. Therefore, it is the successor item for an item that has been phased out.

EAN number

Item number category of the European Article Number (EAN) numbering system. It specifies how Comarch ERP Enterprise system determines an EAN to be assigned internally and which test criteria an EAN of this category must satisfy.

Item categories

Alias items

Alias items are also often called “virtual items.” They are used to sell the same item under different numbers and descriptions, for instance to price them differently according to their use. These items do not actually exist as independent items. They are neither produced, stored, nor purchased.

Pseudo item

A pseudo item is an item that is only needed once. Low-value items and items that are not contained in the assortment can also be managed as pseudo items. Pseudo item data is entered into the system. This item data comprises purchasing data and sales data. Because pseudo items cannot be warehoused, there is no inventory management data and, as a consequence, there is also no production or planning data for them.

Material categories

Storage unit

Storage unit is a general term for all the storage and packaging materials used during storage, transport, and shipping of an item. Storage units are items of the Storage unit material category.

Reference item

A reference item must always be considered in conjunction with variant items. Reference items are not real items; they cannot be purchased or sold. They merely combine important information for the variant items connected with them and are used as a template for generating variant items.

Kit item

A kit item is a material category. Kit items have at most base, purchasing and sales data. They are the basis for creating a kit. A kit includes all the item components that belong to a kit item.

Variant items

An item can be sub-divided even further through variant items. Any terms can be used for variants, such as colors or qualities, for example. The term identifies the variant item. It is either always connected with the item identification, because it extends the identification of the reference item, or it is created as a variant item with its own identification, which is different from the reference item. Inventory management and inventory valuation, complete pricing and material requirement are located on the variant item level. Depending on the use of the variants, special functionalities can only be managed for the reference item. These then apply to all the corresponding variant items.

Identifiers

Batches

A batch is one of the possible identifiers for an item. Batch management means that part of the inventory of an item is identifiable with a batch number. An expiration date is always assigned to a batch. Warehouse inventory management is carried out at item and batch level.

Lots

A lot is one of the possible identifiers for an item. Lot specification means that part of the inventory of an item is identifiable with a lot number. Warehouse inventory management is carried out at item and lot level.

Serial number with inventory management

A serial number with inventory management is always assigned to one quantity unit of a given item. Such an identifier is often used e.g. for electric devices.

Serial number without inventory management

A serial number without inventory management is a special identifier. Such numbers are not used to monitor inventory levels but are only assigned to each unit when a given item is sold. Identifier settings determine whether supplier identifier numbers are used or custom numbers are assigned. In this case, a supplier identifier number can be saved as additional information. In order for information on a given identifier’s inventory levels to be available, the relevant identifier number must be specified for each quantity transaction.

Description of the view

Inventory management data can only be created for items of the Material category which should be stored in the warehouse.

The user cannot enter inventory management data for kit items. In the upper right corner of the Items application, it is possible to change the view according to the scope of data to be entered, e.g. from base data to inventory management data.

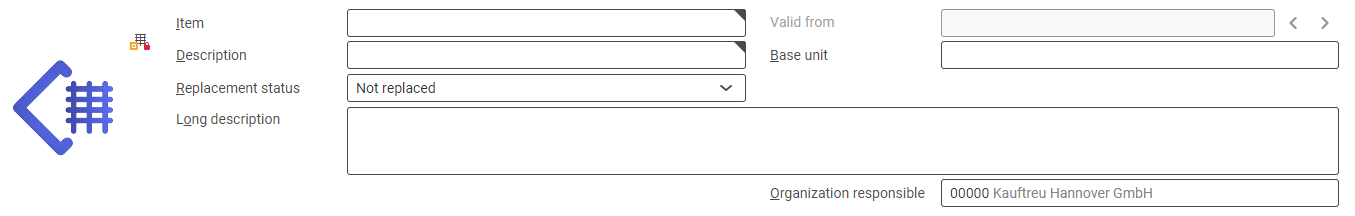

Header

The header enables the user to enter base data for an item. The header is identical in every view. A description of both the type of data that can be created in the identification pane and of the Base view can be found in the Items article.

Work pane

The Inventory Management view is composed of the following tabs:

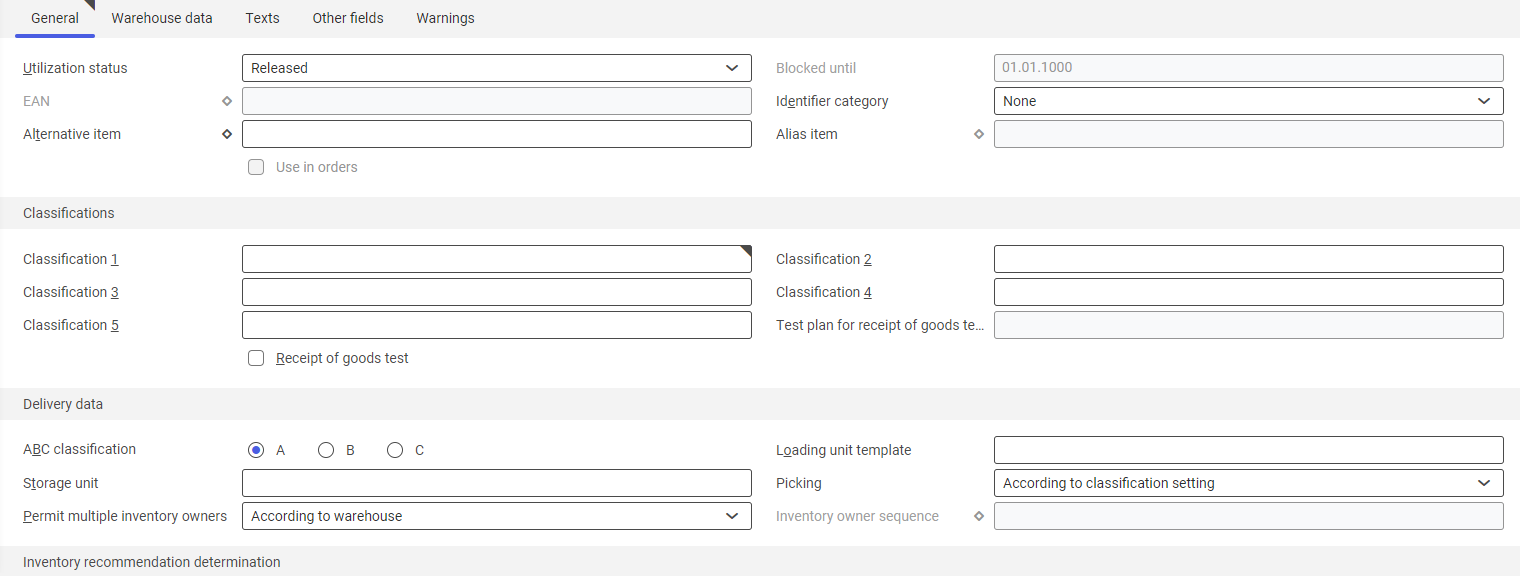

General tab

Among other information, the General tab contains the inventory management data of a given item; the data is visible under all views, but can be edited only in the Inventory Management view. This information serves as the basis for entering more data in the current view.

Besides this data, the user can enter other information for an item in the following sections:

- Classifications

- Delivery data

- Inventory count

- Identifier defaults

- Reservations

- Storage strategies

- Storage restriction

Available fields:

- Utilization status – it allows defining whether a given item may be used in the inventory management process. Available options include:

- Released – it is the default status as set in the Customizing application. If this status is selected, it is possible to use the inventory management data of a given item in inventory processes.

- Blocked – it blocks inventory management data and its use in inventory processes. If this status is selected, it is also required to specify the time period until which a given item is to be blocked.

Unless otherwise pre-set in the Customizing application, inventory management data is set to Released upon its creation.

If the utilization status is set to Blocked, the user can indicate the date until which a given item will be blocked in inventory processes.

An item with the Released status can be used in inventory processes.

- Blocked until – if an inventory item’s utilization status is Blocked, this field should be used to enter the date until which the item is to be considered blocked. The default date is 31.12.9999. If the date entered is overshot, the utilization status remains Blocked, but the the item can be used in inventory processes again.

- EAN – this field displays the European Article Number that can be defined in the Base view. The field becomes available after header data is saved.

- Identifier category – options in this field can only be selected for items of the material category Inventory item or Reference item. Available options include:

- None

- Batch

- Lot

- Serial number with inventory management

- Serial number without inventory management.

An identifier category can only be changed if a given item has not been used in any document yet. Changing an identifier category for a variant item refers to all its variants. Such a change can only be made to a currently valid version.

- Alternative item – it displays alternative items defined in the Base view

- Alias item – it displays an alias assigned to a given item. Alias items do not actually exist. When checking availability, the system considers a real item, not an alias item. An alias item contains only base data.

- Standard variant item – this field is only available for reference items. It displays a default variant for a reference item that can be specified in the Base view.

- Reference item – this field is only available for variant items

- Allow different valuation prices (parameter) – this parameter is only available for variant items. It can be used to determine whether prices set for a relevant reference item are to be applied to the variant item or to the base item.

If the parameter is activated, prices entered in the Financials view are used for the variant item. Otherwise, prices from the reference item data are used.

- Use in orders (parameter) – this parameter controls the use of pseudo items. It can be adjusted in the Base view.

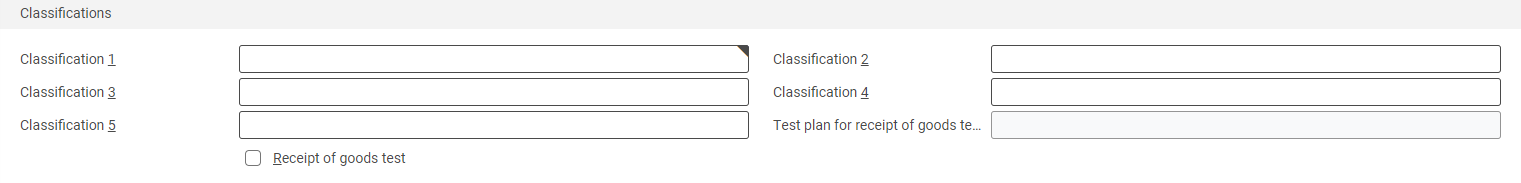

Classifications section

- Classification 1 – it is possible to assign an item to an inventory item classification 1. Assigning an item to a classification simplifies searching for that item. The Classification 1 field must always be filled with a valid entry while creating item inventory management data. User-defined fields can be created on the Other fields tab to further classify an item.

- Classification 2, 3, 4, 5 – an item can be assigned to additional classifications. Classifications can be created in the Classifications application in the Base framework. Completing these fields is not mandatory.

- Receipt of goods test (parameter) – this parameter makes it possible to define whether a quality check should be performed when receiving a given item. The parameter is activated if the Quality management function has been activated for a relevant organization in the Customizing application. For organizations above the site level or in a single-site environment, it is the active OLTP client organization; for all others, it is the active organization of the current site.

- Test plan for receipt of goods test – this field is used to enter a specific test plan for the receipt of goods test. This field is activated only if the Quality management function has been activated in the Customizing application.

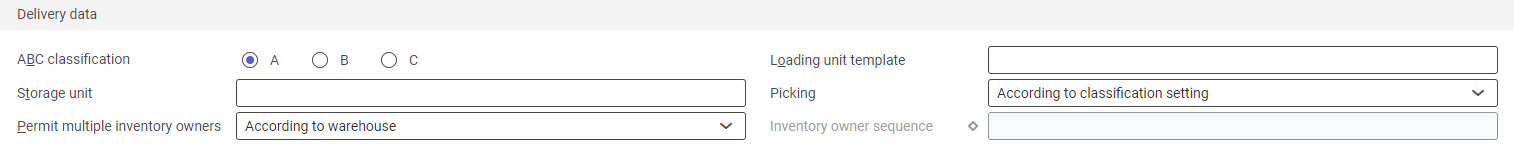

Delivery data section

- ABC classification – this kind of classification classifies items as A, B, or C items. An item with the highest turnover is assigned the A classification. B and C items have a respectively lower turnover. The following options can be selected:

- A

- B

- C

If ABC storage is activated for a given warehouse, an item is put away according to a storage location overrun rule saved for this warehouse. ABC classifications are not considered for withdrawals.

- Loading unit template – in this field, the user can assign a loading unit template to an item. A loading unit is a summary of items in or for a suitable storage unit in order to store or ship it. A loading unit template assigned in this field is used for generating a loading unit. The entry in this field is optional.

- Storage unit – in this field, the user can select a storage unit. A storage unit is a general term for all the storage and packaging materials used during the storage, transport, and shipping of an item. Storage units are items of the Material category. A storage unit assigned in this field is used in inventory processes as a default unit. However, the user can enter another unit for manually created inventory postings and requisitions. The entry in this field is optional.

- Picking – in this field, it is necessary to specify in what way order items related to a given item should be retrieved from warehouses managed by the main warehouse. The setting determines whether picking items containing a given item will be considered when generating inventory orders. One of the following options should be selected:

- According to classification setting

- Any

- Only order based

Picking items containing a given item are only taken into account when creating an inventory order if it is generated for only one picking – including all orders.

- Permit multiple inventory owners – in this field, it is possible to specify whether inventory belonging to several owners should be taken into account for a given item:

- No – only one owner’s inventory can be taken into account

- According to warehouse – the inventory of several owners is taken into account in a sequence defined for a storage location in the Storage locations application (Priority origin field)

- According to sequence – the inventory of different owners is taken into account in a sequence defined in the Storage locations application in the Priority origin field. The field is editable if the Multiple inventory owners function has been activated in the Customizing application.

- Inventory owner sequence – the field is active if the Multiple inventory owners function has been activated in the Customizing application and the According to sequence option has been selected in the Permit multiple inventory owners field. In the Inventory owner sequence field, it is necessary to specify from what owners and in what sequence inventory is to be retrieved. By selecting the diamond button to the left of the field, it is possible to open a dialog box used for determining the order of inventory owners. The sequence may be changed by selecting a row and moving it up or down with appropriate arrow buttons. After the dialog window is closed, the field displays the first inventory owner within the sequence. When multiple inventory owners are entered, the diamond button is displayed in black. A user who is a co-owner may select suppliers and internal companies:

- with which consignment contracts have been signed or

- for which settings have been defined with regard to inter-company billings with a site’s location.

It is also possible to exclude inventory owners from this procedure, despite their contracts, by not entering them into the table.

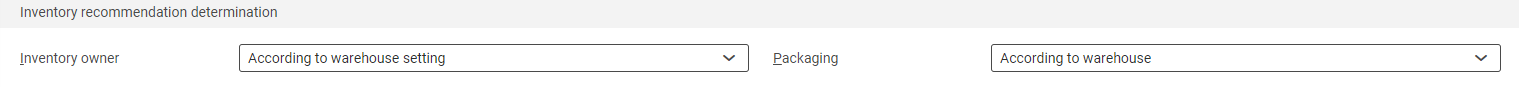

Inventory recommendation determination section

This section is available if the parameter Manage inventory in logistic units has been selected for the Warehouse inventory function in the Customizing application.

Available fields:

- Inventory owner – in this field, it is necessary to define a priority with which an inventory owner is taken into account when determining inventory recommendations for items. Available options include:

- According to warehouse settings – consideration of an inventory owner when determining inventories to be released depends on warehouse settings

- Consider at first – an inventory owner is considered first in determining inventories to be released. Second, the system considers the age of an item or variant. Finally, it considers its package. This setting can be used when the user wants to use external suppliers’ inventory.

- Consider at last – an inventory owner is considered last in determining inventories to be released. First of all, the system considers the age of an item or variant, and then its packaging. This setting is used when using lots that expire first.

- Packaging – in this field, it is necessary to specify whether and how packaging that is marked as required is to be taken into account in determining a given item’s inventory recommendations. If a packaging is not marked as required, then the setting is not considered. Available options include:

- According to warehouse settings – consideration of a packaging when determining inventories to be released depends on storage location settings

- Prefer small packaging – recommended inventories are packed in the smallest possible number of packaging units. As a result, open external packagings and remaining quantities are utilized.

- Prefer large packaging – recommended inventories are packed in packagings with as many pieces as possible

- Do not suggest packaging – inventory recommendations are packed only in a requested unit. External packagings are not taken into account.

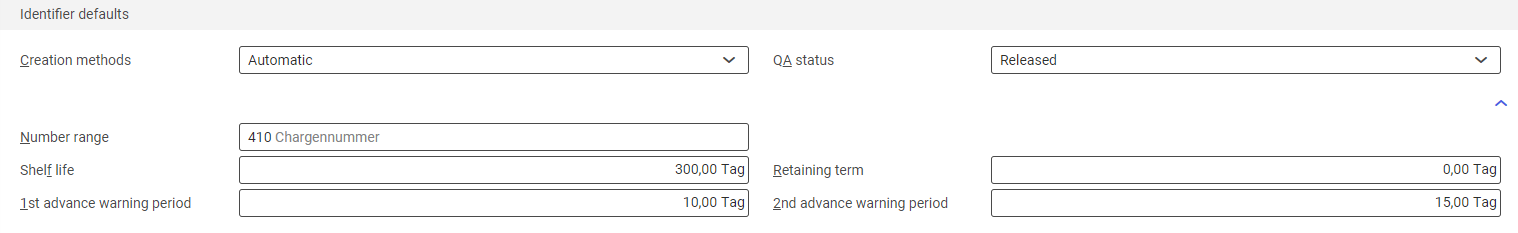

Identifier defaults section

An item can be further differentiated using identifiers. The following identifiers are available:

- Batch

- Lot

- Serial number with inventory management

- Serial number without inventory management

In this section, it is possible to define default values for identifiers. Identifier master data can be specified in the following fields.

Available fields:

- Creation methods – in this field, it is necessary to select a corresponding creation method from the selection menu. Available options include:

- Automatic – in this case, the system automatically assigns an identifier number in orders and receipts of goods, and generates a related identifier master record, if required

- Manual – in this case, all identifiers must be manually entered in the Identifiers application available in the Inventory management framework. Only existing identifiers can then be assigned through their number in other vouchers.

- QA status – in this field, the user can select a quality assurance status. Available options include:

- Released

- In quarantine

- Blocked

A QA status entered in this field is used as default when creating new identifiers for an item.

- Number range – in this field, it is necessary to enter a number range. An assigned number range is used if the creation method is set as Automatic and provides identification numbers for identifiers to be generated automatically. Such numbers identify an identifier uniquely within a given item.

- Guarantee period – in this field, it is necessary to enter a guarantee period for an item sequenced in serial numbers. A guarantee period is used for calculating the guarantee period of an identifier. The field is divided into two parts. In the left field, it is necessary to enter the number for a time period. The right field makes it possible to define a time unit, for instance day, month, or year. The field is activated only if the option Serial number with inventory management or Serial number without inventory management has been selected in the Identifier category field.

- Shelf life – in this field, it is necessary to enter the shelf life of an item sequenced in batches. The date is used to calculate the minimum shelf life of a batch. It determines the date up to which the usability of a batch is guaranteed. The field is divided into two parts. In the left field, it is necessary to enter the number for a date. The right field makes it possible to define a time unit, for instance day, month, or year. The field is activated only if the option Batch has been selected in the Identifier category field.

- Retaining term – in this field, it is necessary to enter the retaining term of an item sequenced in batches. A retaining term is used for calculating the retaining date of a batch. It determines the date up to which a given batch will not be included in automatic batch allocation. The field is divided into two parts. In the left field, it is necessary to enter the number for a time period. The right field makes it possible to define a time unit, for instance day, month, or year. The field is activated only if the option Batch has been selected in the Identifier category field.

- 1st advance warning period – in this field, it is necessary to enter the first advance warning period for an item sequenced in batches. An advance warning period is used for calculating the advance warning date of a batch. The field is divided into two parts. In the left field, it is necessary to enter the number for a time period. The right field makes it possible to define a time unit, for instance day, month, or year. The field is activated only if the option Batch has been selected in the Identifier category field.

- 2nd advance warning period – in this field, it is necessary to enter the second advance warning period for an item sequenced in batches. An advance warning period is used for calculating the advance warning date of a batch. The field is divided into two parts. In the left field, it is necessary to enter the number for a time period. The right field makes it possible to define a time unit, for instance day, month, or year.

The field is activated only if the option Batch has been selected in the Identifier category field.

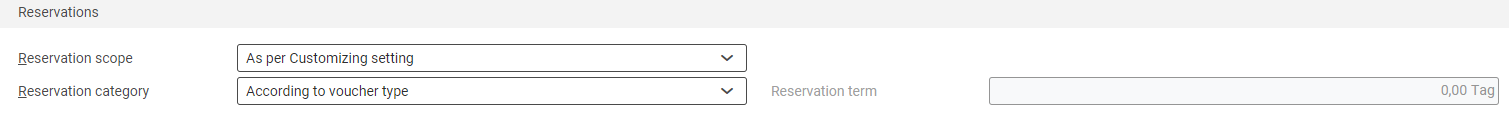

Reservations section

This section is only visible if the Fixed reservations function is activated for the active OLTP client in the Customizing application.

- Reservation scope – in this field, the user can specify the details of reservations for a given item, such as whether and in which frame the reservations will take place. Available options include:

- As per Customizing setting

- No reservations

- Inventory

- Inventory and planned receipts

The Inventory and planned receipts option is only available if the Allow reservation of planned receipts parameter has been activated in the Customizing application.

- Reservation category – in this field, it is possible to specify reservation categories for a given item. Available options include:

- According to voucher type

- Manual

- Automatically with reservation term

- Automatically without reservation term

This field is non-editable if the creation of reservations is restricted by the No reservations option set in the Reservation scope field.

- Reservation term – in this field, it is necessary to define a date from which an automatic reservation is to be created. An automatic reservation occurs when the time (measured in business days) between the current date and a required date is equal to or less than the specified reservation period.

The field is only editable if the Use reservation term field is set as Yes.

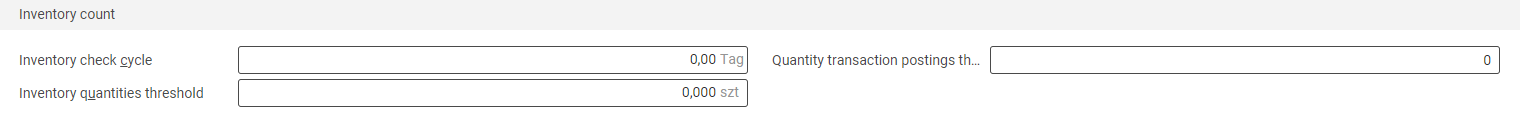

Inventory count section

- Inventory check cycle – if required, this field allows specifying the time period after which an inventory count must be repeated for a given item. Specifically for the repeated inventory count process, an inventory count list can be generated for a given item that includes only those items for which an inventory check cycle has been defined. If the value 0 is entered in this field, a given item will not be considered for a repeated inventory count.

- Quantity transaction postings threshold – if required, this field allows entering the number of material reservations as a threshold value to subsequently carry out an inventory count for a given item. The system counts each material posting completed using a posting key for which the Quantity transaction function has been activated. In the special case of recurring inventory counts, an item selection list can be generated that contains only those items for which a threshold value for quantity transaction postings has been specified. If the threshold value is exceeded, a given item will be placed on an appropriate inventory count list. If the number of reservations is below this value, it is excluded. If the value 0 is entered in this field, the threshold value is not analyzed.

- Inventory quantities threshold – if required, this field allows entering a quantity as a threshold value with which it could be specified up to what quantity an item should be considered for a repeated inventory count. This quantity always refers to an item’s inventory management unit. The unit cannot be changed. In the special case of recurring inventory counts, an item selection list can be generated that contains only those items for which a threshold value for an inventory quantity has been specified. In this way, it is possible e.g. to generate lists to inventory small item quantities. If an item quantity is below the threshold value, then a given item will be placed on an appropriate inventory count list. If the quantity exceeds the threshold value, then the item will be excluded.

If the value 0 is entered in this field, the threshold value is not analyzed.

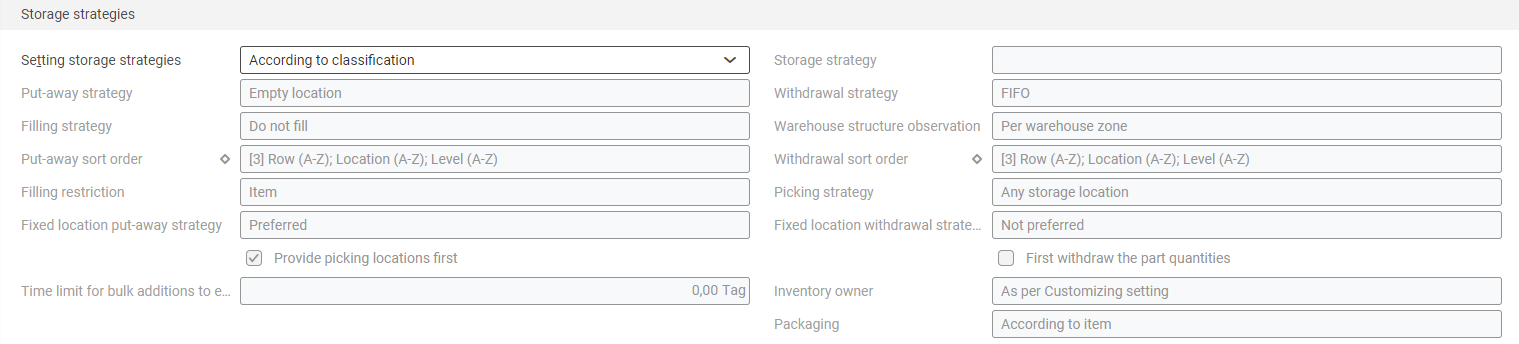

Storage strategies section

Available fields:

- Setting storage strategies – in this field, it is necessary to determine what storage strategies are used for a given item. One of the following options should be selected:

- According to the warehouse zone – storage strategy settings defined for a warehouse zone are used for the item

- According to classification – storage strategy settings defined for an inventory item classification 1 are used for the item

- Manual – activating this option unblocks other editable fields. In these fields, it is possible to define storage strategies for particular items.

- Storage strategy – storage strategies comprise of several individual strategies that together specify the procedure during warehouse receipt or withdrawal processes in warehouses categorized in storage locations. The determination of a storage strategy to be used is done in the following sequence:

1. Item and warehouse (Inventory data in the Items application, Inventory Management view)

2. Item (the Inventory Management view in the Items application)

3. Inventory item classification 1 (the Classifications application)

4. Warehouse zone (the Warehouses application)

5. Warehouse (the Warehouses application)

6. Inventory order (the Inventory order types application) If a valid storage strategy has been found at a given level, the levels under it are ignored. More information may be found in the Storage strategies article.

Available fields:

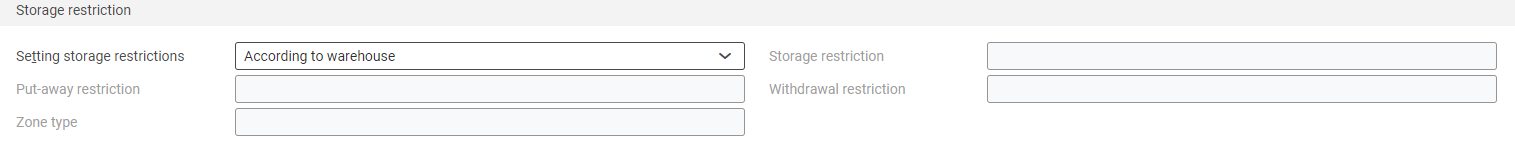

- Setting storage restrictions – this field allows determining what storage restrictions are to be used for an item. One of the following options should be selected:

- According to warehouse – storage restriction settings defined for a warehouse site are used for the item

- According to classification – storage restriction settings defined for an inventory item classification 1 are used for the item

- Manual – activating this option unblocks other editable fields. In these fields, it is possible to define storage restrictions for particular items.

- Storage restriction – the field is active if the Manual option has been selected in the Setting storage restrictions field. The field allows selecting one of the available storage restriction options. After selecting a storage restriction, click the [Validate] button to transfer the settings of a given storage restriction to associated fields. If one of the features of the selected restriction is changed, the Storage restriction field becomes blank. In this case, it is necessary to configure storage restriction settings individually for a given item. Note that changed settings refer to a specific item only. It is possible to define storage restriction settings generally for a given item with no need to select a particular restriction. The determination of a storage restriction to be used is done in the following sequence:

1. Inventory data (the Inventory Management view in the Items application)

2. Item (the Inventory Management view in the Items application)

3. Inventory item classification 1 (the Classifications application)

4. Warehouse (the Warehouses application)

5. Inventory order (the Inventory order types application)

If a valid storage restriction has been found at a given level, the levels under it are ignored. If there is no storage restriction saved at any level, warehouse receipt and withdrawals are processed without the use of a storage restriction.

Warehouse data tab

The Warehouse data tab displays a list that can be used to display an item with reference to a specific warehouse and define warehouse logistics data. In a single row of the list, several headers display warehouse logistics data for the currently loaded item. The display can be controlled using the toolbar buttons.

In addition to the [New], [Delete], and [Sort] buttons, the toolbar contains other buttons described in the chapters below.

- [Delivery data] button

- [Inventory recommendation determination] button

- [Reservations] button

- [Inventory count] button

- [Storage strategies] button

- [Storage restrictions] button

To enter warehouse data, it is first necessary to select the [New] button in the toolbar. The following field will be displayed:

- Warehouse – in this field, it is necessary to enter a relevant warehouse for which the data of the currently displayed item is to be registered or displayed

[Delivery data] button

Activating the button displays the Delivery data section. The section makes it possible to define individual delivery settings for an item-warehouse combination. More details may be found in the Delivery data section chapter.

[Inventory recommendation determination] button

Activating the button displays the Inventory recommendation determination section. The section makes it possible to define what rules are to be applied for an item-warehouse combination. More details may be found in the Inventory recommendation determination section chapter.

[Reservations] button

Activating the button displays the Reservations section. The section makes it possible to define individual reservation settings for an item and warehouse. More details may be found in the Reservations section chapter.

[Inventory count] button

Activating the button displays the Inventory count section. The section makes it possible, for instance, to define an inventory quantities threshold. More details may be found in the Inventory count section chapter.

[Storage strategies] button

Activating the button displays the Storage strategies section. The section’s Setting storage strategy field makes it possible to define what storage strategies are used for an item-warehouse combination. More details may be found in the Storage strategies section chapter.

[Storage restrictions] button

Activating the button displays the Storage Restrictions section. The section makes it possible to define particular item and warehouse data. More details may be found in the Storage restriction section chapter.

Texts tab

The tab makes it possible to enter additional texts associated with an item. They are usually used in document printouts.

Refer to the Text editor chapter in the Operating Guidelines article for more details on entering texts.

Other fields tab

The Other fields tab may be used to enter user-defined fields that provide additional information. The fields are essentially associated with a business unit; this is why they are visible in the case of all items. However, values entered by the user on this tab refer only to a displayed item. Field types and their meaning have been described in the article Operating Guidelines.

Customizing

The Items article provides information about settings in the Customizing application that are associated with relevant views of the Items application.

Business entities

The following business entities are relevant for the Items application, Inventory Management view that can be used for:

- Assigning authorizations

- Providing activity definitions

- Importing or exporting data

Inventory item:

com.cisag.app.inventory.obj.InventoryItem

The business entity belongs to the following business entity group:

com.cisag.app.inventory.MasterData

Authorizations

Authorizations can be assigned by means of authorization roles, as well as by assigning an organization. The authorization concept is described in the Authorizations article.

Special capabilities

There are no special capabilities for the Items application, Inventory Management view.

Organization assignments

To ensure that a person can use the Items application, Inventory Management view, the user must be assigned to an organization that is connected to at least one of the following organization structures:

- Inventory management

Special features

The Multi-site and single-site with content-cased authorizations chapter in the Items describes organization-related features. There are no special features in a pure single-site environment.

Authorizations for business partners

The Items application, Inventory Management view is not released for the business partners.