Topic overview

Data for distribution recommendations is generated as a result of material requirements planning in a multi-site environment. Material requirements planning determines both primary and secondary requirements. Primary requirements include all items that must be produced or purchased because they are the object of specific orders or demand forecasts, or because stock levels have fallen below minimum or safety inventory levels in a warehouse.

Production recommendations can be generated from the planning for the portion of a calculated demand that must be produced. Secondary requirements include all materials (items) that are necessary for the production of primary requirements (production items). These can also be production items themselves, which in turn require materials for their production.

This demand can be covered:

- Internally, through production processes, which require semi-finished goods (i.e. materials which are production elements themselves) – additional production recommendations are generated

- Internally, by the company itself – distribution recommendations are generated

- Externally, by suppliers – purchasing recommendations are generated

As a precondition for generating distribution recommendations, it is necessary to select the Internal purchasing parameter in the Items application (Planning view, Purchasing data (internal) section).

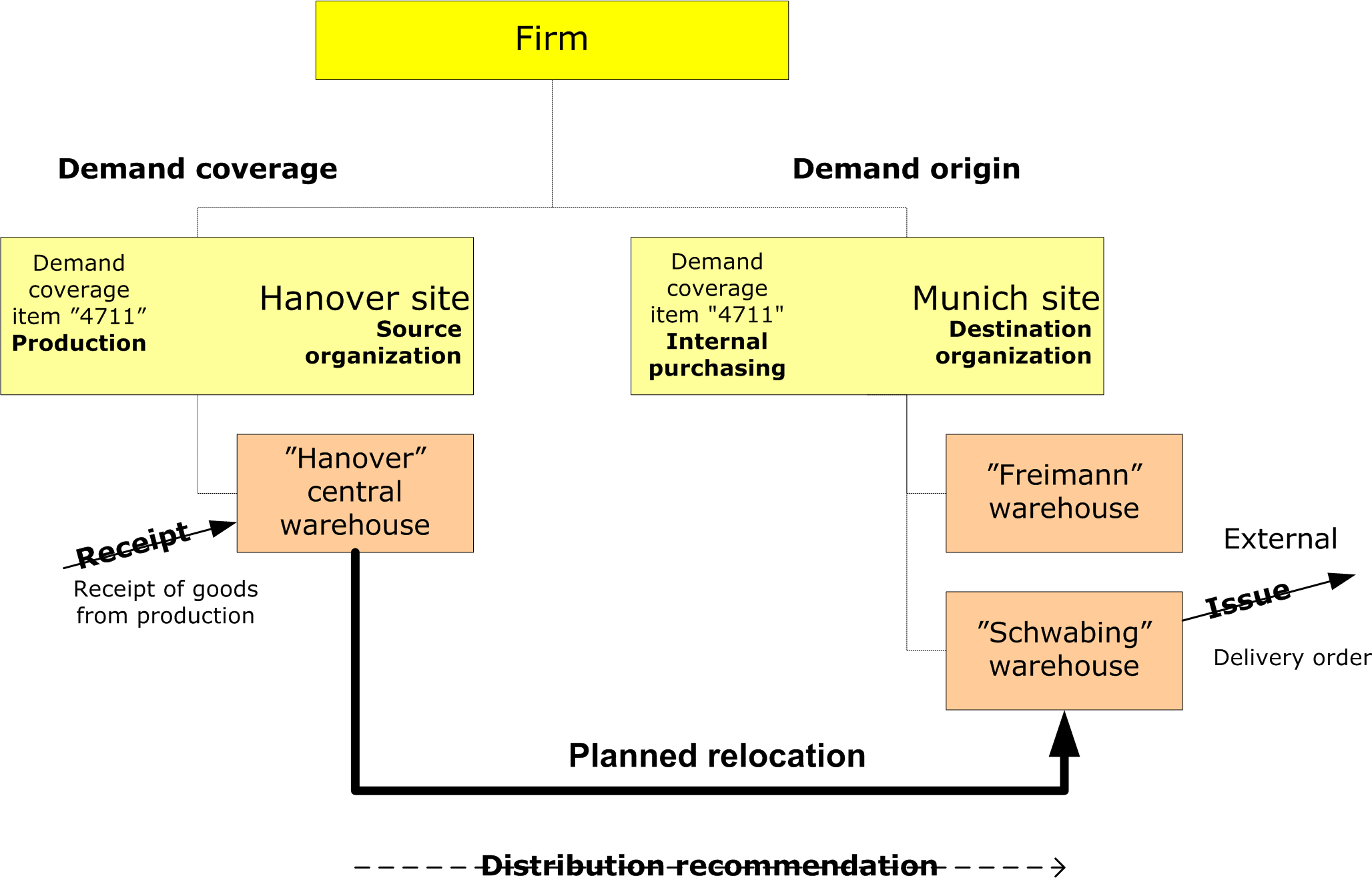

This article describes how distribution recommendations are generated based on a calculated demand for internally purchased items within material requirements planning.

The result, i.e. the generated distribution recommendation, can be displayed

and further processed in the Distribution recommendations application.

Definitions of terms

Distribution recommendations

Distribution recommendations are used to cover internal demand in multi-site environments. They arise whenever the inventory and anticipated receipts do not meet demand ad a particular location. A distribution order can be generated from a distribution recommendation, which enables the required item to be transferred from a source warehouse to a target warehouse across organizations.

Processes

Distribution recommendations are generated as a result of material requirements planning in a multi-site environment only. An overview of multi-site issues can also be found in the Multi-site article.

Distribution recommendations are always generated when the warehouse inventory and expected receipts can no longer cover the demand within a site (inventory logistics organization) of a corporate structure and the demand coverage of a given item is set to Internal purchasing (in the Items application, Planning view). The main supplier must then be a site (internal inventory logistics organization) with the Supplier partner role.

If the user would like to change the demand coverage temporarily to external purchasing or production, it is possible to do so in the Material requirements query application. As a precondition for this, the corresponding purchasing and/or production data must be available.

Distribution recommendations always refer to two organizations. One organization – the source organization – covers the demand of the destination organization. The objective is the relocation of a certain quantity of an item from the inventory of a particular warehouse of the source organization to the inventory of a warehouse of the destination organization. This relocation is carried out by means of distribution orders, which are generated from distribution recommendations.

Of course, distribution recommendations can also be used in commercial enterprises.

Application description

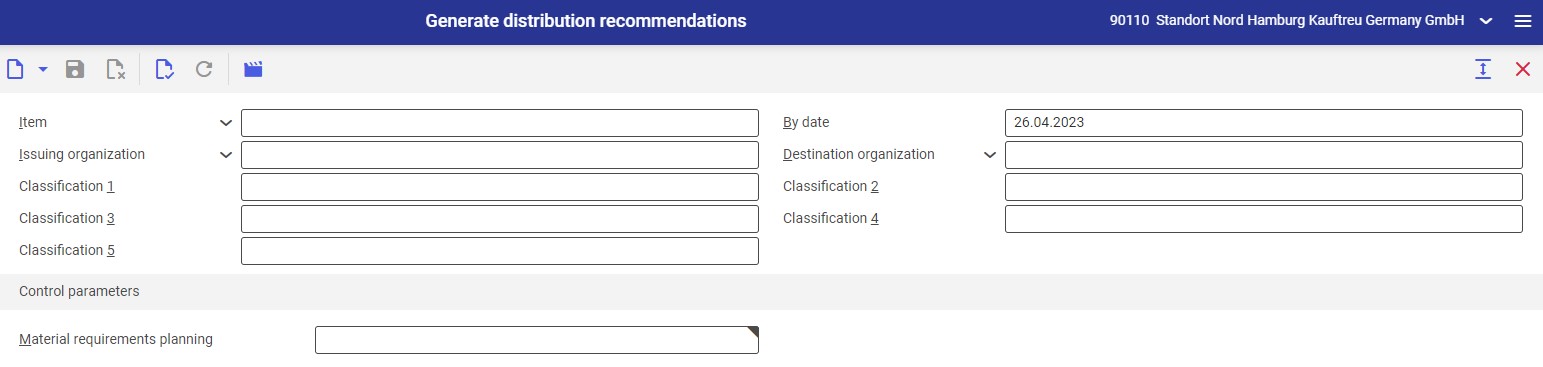

The Generate distribution recommendations application consists of a header and work pane. Selection criteria are entered here in order to limit the items and any other applicable characteristics, based on a specific material requirements planning for which the system is to generate distribution recommendations.

The application window is divided into two areas:

- Application header – it allows selecting data for which a distribution recommendation is to be generated

- Control parameters – it allows defining material requirements planning according to which distribution recommendations are to be generated

Application header

The application header contains the following fields and buttons:

- [New] – it allows generating a new distribution recommendation

- [Generate distribution recommendations] – it opens the Generate distribution recommendations dialog window, which allows defining a recommendation calculation date and adjusting batch job settings

- Item – select the items for which distribution recommendations are to be generated

- By date – enter a date by which distribution recommendations will be generated

- Source organization – select the source organization. Only secondary requirements that can be covered by such an organization according to the planning are taken into consideration. The source organization must be assigned the Supplier partner role.

- Destination organization – select the destination organization. Only primary requirements that can be covered by such an organization according to the planning are taken into consideration. The destination organization must be assigned the Customer partner role. It must also be a purchasing organization.

- Classification 1 – a classification can be entered as a selection criterion. Existing classifications of the type Inventory item classification 1 are permissible.

- Classification 2 – a classification can be entered as a selection criterion. Existing classifications of the type Inventory item classification 2 are permissible.

- Classification 3 – a classification can be entered as a selection criterion. Existing classifications of the type Inventory item classification 3 are permissible.

- Classification 4 – a classification can be entered as a selection criterion. Existing classifications of the type Inventory item classification 4 are permissible.

- Classification 5 – a classification can be entered as a selection criterion. Existing classifications of the type Inventory item classification 5 are permissible.

Control parameters

The control parameters are used to select the underlying material requirements planning.

- Material requirements planning (required) – select the material requirements planning for which distribution recommendations are to be generated. Note that it is only possible to process the material requirements planning to which the user is assigned as the editor in the Items application (Planning view). Material requirements planning can be defined in the Material requirements planning application.

The generation of distribution recommendations is noted within the planning data set. Consequently, another call-up with the same selections without roll-up of the material requirements planning produces no result. It is not sufficient to delete the generated distribution recommendations.

However, existing distribution recommendations will be considered when a planning run is repeated. If the entire calculation is to be performed anew, the distribution recommendations must be deleted beforehand. It is possible to exclude the distribution recommendations in material requirements planning; likewise, they can be included according to their status.

One distribution recommendation line item is generated for each planning period with a planned demand. The planning period date is entered as the due date of the distribution recommendation.

Distribution recommendations are generated only for items with the Internal purchasing origin configured in the Items application (Planning view).

Instructions: Generate distribution recommendations

Complete the following steps to generate distribution recommendations:

- Open the Generate distribution recommendations application

- Use the [New] button to open a new application form

- Filter data for recommendation generation according to fields available in the application header

- In the Material requirements planning field, select material requirements planning based on which the system should generate distribution recommendations. Material requirements planning can be defined in the Material requirements planning application.

- Select the [Generate distribution recommendations] button. The Generate distribution recommendations dialog window will open.

- Define a start date from which recommendations are to be generated

- Run the recommendation generation process by clicking [In background]

- Generated distribution recommendations can be displayed in the Purchasing framework’s Distribution recommendations application

Application-related actions

The system considers all items meeting selection criteria and generates distribution recommendations for those items.

Selecting the [Generate distribution recommendations] button displays the Generate distribution recommendations dialog window. The window’s Parameter tab contains the following fields:

- Setting via date – in order to set a production date, use one of the following options:

- Use execution date – it activates the Offset field. An execution date and an offset are used after this option is selected.

- Use specified date – it clears the Offset field. A date defined in the By date field is used after this option is selected.

- Offset – selecting this option increases the execution time by a specified number of days and the result is applied to the By date field

The status is then set as Completed. The system sends a message confirming the number of generated distribution recommendations. Results can be checked in the Distribution recommendations application.

Customizing

No settings need to be made for the Generate distribution recommendations application in the Customizing application. The Multi-site function must be activated in the Customizing application to work with distribution recommendations. In addition, purchasing and sales organizations

involved in the distribution recommendations must exist.

Business entities

There are no relevant business entities for the Generate distribution recommendations application.

Authorizations

Authorizations can be assigned by means of authorization roles, as well as by assigning an organization. The authorization concept is described in the Authorizations article.

Special capabilities

The Generate distribution recommendations application has no special capabilities.

Organizational assignments

If the Content-based authorizations function is activated in the Customizing application, a person can only use the Generate distribution recommendations application if an organization that is linked to at least one of the following organizational structures has been assigned to him or her in the partner master data:

- Inventory Management

Special features

Distribution recommendations can only be generated by an employee who is assigned as the editor in the respective material requirements planning.

Authorizations for business partners

The Generate distribution recommendations application is not released for business partners.

Application-based actions

All items corresponding to the selection are considered, and distribution recommendations are generated for these, provided that they are the object of planned demands.

The status is set to Entered. The system provides the user with a confirmation message with the number of generated distribution recommendations. The result can be viewed in the Distribution recommendations application.