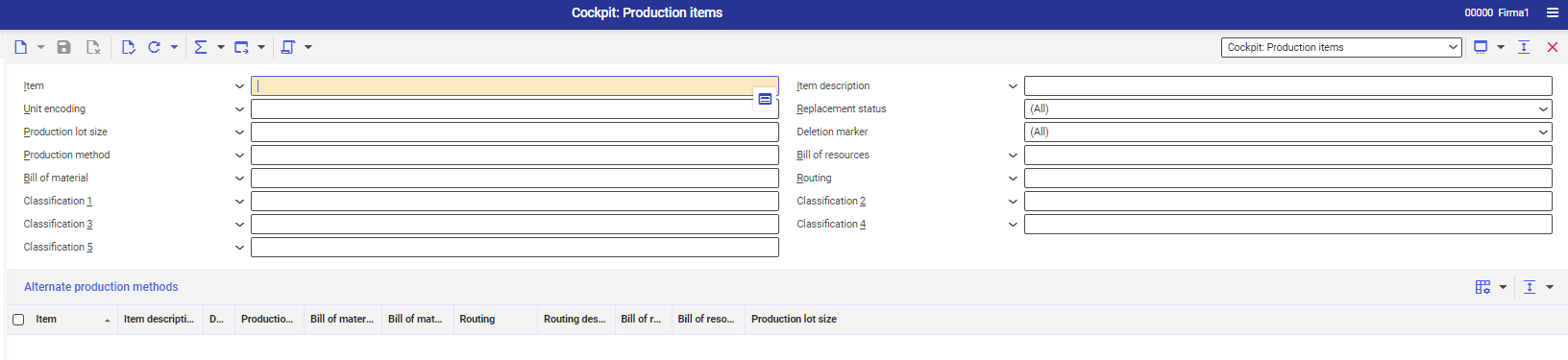

The application Cockpit: Production items allows for previewing production items with created and defined Production view in the Items application. The action executed from the level of the cockpit allows for creating several calculations at the same time.

The data displayed in search results is retrieved from the Items application.

The buttons available in the applications of Cockpit type and the functionalities of these applications (e.g., handling fields available in the identification pane and additional sections) are described in article Batch applications.

The application is composed of the identification pane and the workspace.

Identification pane

In the identification pane, there are fields allowing for filtering search results according to selected criteria.

- [Select action] → [Generate calculations] – allows for generating calculations for selected items. Opens Generate calculations dialog window. More information regarding cost calculations can be found in the Generate calculations dialog window chapter.

Fields available in the application header make it possible to filter data. The following fields are available:

- Item – allows for selecting an item or more items for which the data in the table should be displayed.

- Item description – allows for selecting description of the item for which the data in the table is to be displayed, defined in the Description of the Items application

- Unit encoding – allows for filtering data according to selected item unit

- Replacement status – allows for filtering data according to the status defined for it in the application Items → Status field. The following options are available:

- (All) – displays all items regardless of their status

- Not replaced – displays items with Not replaced status

- Replaced – displays items with Replaced status

- Replaced if availability = 0 – displays items replaced because of their unavailability

- Expired – displays items with Expired status

- Expired if availability = 0 – displays items expired because of their unavailability

- Production lot size – allows for filtering data with selected lot size

- Deletion marker – allows for filtering items according the definition of the deletion marker parameter. The following options are available:

- (all) – displays items marked and not marked for deletion

- Marked as deleted – displays items marked for deletion

- Not marked as deleted – displays items not marked for deletion

- Production method – allows for filtering by items to which selected alternative production method is assigned in the application Items → Production view → Alternate methods section.

- Bill of resources – allows for filtering by items to which a specific bill of resources is assigned in the application Items → Production view → Bill of resources section.

- Bill of material – allows for filtering by items to which a specific bill of material is assigned in the application Items → Production view → Bill of material section.

- Routing – allows for filtering by items to which a specific bill of material is assigned in the application Items → Production view → Bill of material section.

- Classification 1 – allows for filtering items with the classification 1 assigned in the application Items, Production view

- Classification 2 – allows for filtering items with the classification 2 assigned in the application Items, Production view

- Classification 3 – allows for filtering items with the classification 3 assigned in the application Items, Production view

- Classification 4 – allows for filtering items with the classification 4 assigned in the application Items, Production view

- Classification 5 – allows for filtering items with the classification 5 assigned in the application Items, Production view

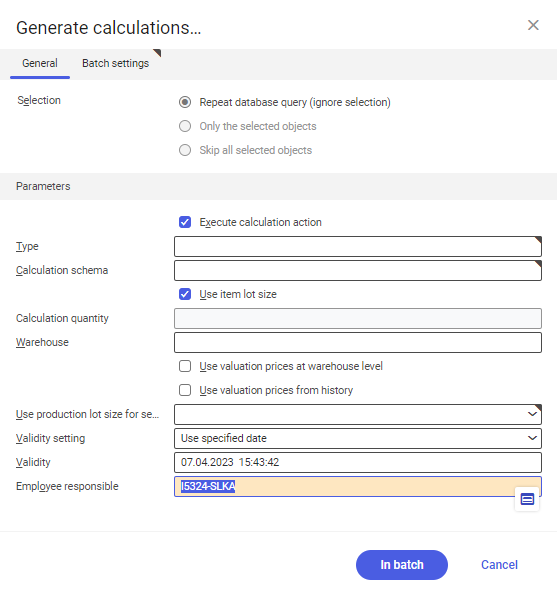

Generate calculations dialog window

The Generate calculations dialog window is displayed after selecting the button [Select action] → [Generate calculations]. It allows for customizing the calculations which will be created for selected items.

The Generate calculations dialog window is composed of the tab General and Batch settings. The tab General contains the following fields and parameters:

- Selection – allows for selecting objects for which the calculation will be created. Available values:

- Repeat database query (ignore selection) – the list of items will be refreshed on the basis of the parameters defined in the application header

- Only the selected objects – the action will be executed for the object selected from the list

- Skip all selected objects – the action will be executed only for the objects not selected on the list

- Section Parameters – allows for defining the settings regarding the calculation. The following fields and parameters are available:

- Execute calculation action – if the parameter is checked, calculations are executed for selected calculation. If the parameter is inactive, the calculation is only created and is not executed.

- Type – allows for selecting the type of created calculation. The calculation type must have been previously created in the Calculation types application.

- Calculation schema – allows for selecting the calculation schema which will be used for calculations. The calculation schema must have been previously created in the Calculation schemas application. In multi-company environments, calculation schemas are assigned to the organization, therefore calculation schemas available for selection are narrowed down to the data defined for selected organization.

- Use item lot size – if the parameter is checked, the calculations will be created for the quantity of the item lot which is defined in the application Items → Planning view → Production data section → Lot size field. For items with lot size equal to 0, if the parameter is activated, the value 1 is used.

- Calculation quantity – allows for defining the item quantity for which the calculation will be executed. If the parameter Use lot size is active, this field is not available. It must be remembered that the lot size can affect used processes and production resources, which can cause different calculation results. Additionally, once the calculation is executed, it is not possible to change the quantity.

- Warehouse – allows for selecting the warehouse thanks to which it is possible to calculate costs on the level of storage areas. If no storage area is selected, it is specified on the basis of the data from the bills of materials for:

- Pre-calculation

- Pre-calculation with order reference

- Pre-calculation with quotation reference

- Preliminary calculation with service item

For the Production order calculation and Final calculation of the production order value, the warehouse is specified on the basis of the production order data.

- Use valuation prices at warehouse level – if the parameter is checked, the prices are determined on the level of the storage areas. If no prices are available on the level of the storage areas, they are determined on the line item level.

- Use valuation prices from history – if the parameter is checked, prices for the calculation are retrieved from the history of prices. The price is fixed in the following way:

- on the basis the price history of the item line for materials,

- on the basis of the history of cost rates for labor costs.

In the case of the production order calculation and the final calculation of the production order value, the price is determined on the basis of the posting date of the production operations. If there is no posting, the date of releasing production order for production is retrieved and if such date is not available, the Validity date of created calculation is retrieved. The cost of materials is determined on the basis of the date included in the Validity date field for created calculation. If material valuation is retrieved from the price list, it is not possible to determine prices on the basis of the valuation from the history.

- Use production lot size for semi-finished goods – allows for selecting the method of considering refitting time for semi-finished goods in a calculation, if they are produced in accordance with the production lot size. The following values are available for selection:

- According to the production lot size of semi-finished goods

- Proportionally if calculation quantity is smaller than semi-finished goods production lot size

- Proportional to calculation quantity

- Validity setting – allows for selecting comparison date settings. Available options:

- Use execution date – date of calculation execution. In the Validity field, the current date is displayed by default

- Use specified date – allows for selecting date in the Validity field

- Validity – allows for defining calculation creation date

- Employee responsible – allows for selecting the contact person and responsible for the calculation. Selected employee must be an employee of the company.

The Batch settings tab allows for defining the settings for the task batch processing.

Table

The table of the application contains table which displays data according to the filters defined in the identification pane.

The following buttons are available in the table:

- Alternate production methods – an additional row will be displayed for the item, containing defined alternate production method

- Define query and result properties – allows for defining a view, adding/deleting columns from the table and modifying sorting settings

- [Hide/Show ranges] – allows for modifying displayed table, the following options are available:

- Hide/Show list header – hides/shows the descriptions of table columns

- Hide/Show line status – hides/shows the column with the line status

- Show grouping and sort area – allows for dragging the name of a column onto displayed area and grouping data according to selected attribute

- Hide grouping and sort area – allows for hiding of the grouping area

- Expand all groups – expands line items grouped in the table.

- Reduce all groups – reduces line items grouped in the table

- Show all areas – displays all columns and descriptions

- Hide all areas – hides all columns and descriptions

More information regarding the configuration of views can be found in article Customizable user interface.

The columns in the table correspond to the descriptions of the fields available in the application header.