Topic overview

Picking refers to the provision of item inventories for downstream processes, e.g. in sales or production. If an item to be picked or delivered is managed in identifiers, an identifier assignment must be made before the item can be picked. The assignment means that the item is made available in exactly this identifier. If the Reservations function is used, reservations are also created with the identifier assignment, otherwise identifier reservations are created. The identifier assignment is not an independent application and is only used as a process within other applications.

This article describes both the manual and automatic assignment of identifiers. Find out, for example, in which processes and under which conditions an identifier assignment can take place. You can also read about the criteria according to which the existing identifiers are assigned to an item. The applications used and their fields, actions and procedures are described in detail in separate article.

Definitions of terms

Identifiers

An identifier enables the identification of specific items or item variants. As identifiers, batch, lot, and serial number are supported.

Identifier reservation

A fixed identifier (batch, lot, or serial number with inventory management) is reserved with an identifier reservation. If, for example, a particular batch is specified in a sales order, then with an identifier reservation the corresponding item quantities are reserved so that these are no longer available for other issues. An identifier reservation is then always used if the function Reservations is disabled or, if it is activated, if in isolated cases other settings impede a reservation. Included among this, for example, is the reservation setting for the utilized warehouse.

Identifier assignments

If an item is managed in identifiers, identifiers must be assigned during picking or during the delivery. If the user did not provide identifiers, the assignment occurs automatically

Batches

A batch is one of the possible identifiers for an item. Batch management means that part of the inventory of an item is identifiable with a batch number. An expiration date is always assigned to a batch. Warehouse inventory management is carried out at item and batch level.

Picking (order)

Picking makes items available, for example, for a delivery to customers or for production. Picking orders include all items that are made available from one warehouse.

Lots

The lot is one of the possible identifiers for an item. Lot specification means that part of the inventory of an item is identifiable with a lot number. The warehouse inventory is managed at item and lot level.

Quality status (QA status)

A quality status or quality assurance status (QA status) can be defined for the warehouse and warehouse zone levels, and in parallel also for the identifier level. Inventory can be analyzed and utilized specifically according to QA status. If QA status is defined for certain inventory both at the warehouse level and for the identifier level, the inventory has the lower QA status.

Reservation

Reservations represent the link of a demand origin to a demand coverage. A reservation is only possible if both items and warehouses match between demand origin and demand coverage.

Serial numbers

Serial numbers are possible identifiers for items. Serial number identification means that every unit of an item is given a serial number that identifies it uniquely throughout the system. In contrast to batches and lots, a serial number is assigned to exactly one item in the 1st item unit. The assignment of serial numbers is differentiated into serial numbers with inventory management and serial numbers without inventory management.

Manual identifier assignment

Manual identifier assignment refers to the assignment of an identifier to an item by the user. Manual identifier assignment is carried out by specifying an identifier in an order line item. The identifier permanently assigns the identifier to the order.

The assignment also applies to all downstream orders in the voucher chain. If, for example, a specific identifier is specified when entering a sales order line item, this identifier also applies to the delivery order, the picking order and any inventory order. In this case, there is no automatic identifier assignment when creating downstream orders. Manual overwriting of the identifier in the downstream orders is also not permitted.

An identifier can be assigned manually for the following order categories, among others:

- Sales order

- Delivery order

- Production order

- Picking order

- Inventory order

- Inventory requisition

- Distribution order

A manual identifier assignment in a delivery order line item is only possible if the warehouse is not divided into storage locations and there is no picking order.

If the process is a withdrawal or a multiple warehouse relocation, the manual allocation also results in a reservation of the required quantity of the identifier at the warehouse concerned. If the Reservations function is not used, identifier reservations are generated instead.

Overwriting an automatically assigned identifier of an inventory order line item is also considered a manual identifier assignment. In this case, the existing reservation is canceled and a reservation is created for the newly specified identifier.

Further information on reservations can also be found in the articles Introduction: Reservations and Identifier reservations.

Manual identifier assignment in the picking order

In the case of manual identifier assignment in the picking order, a higher identifier quantity can be confirmed than the total quantity of items to be picked. As long as the picking order is not completed, its demand is therefore increased. This situation is referred to as over-demand. You can see how high the over-demand is in the Availability query application, Origin view. There, all individual demands for a picking order line item are visible in the Open column. The sum of these individual open quantities minus the quantity to be picked is the over-demand.

The following examples are used to explain the relevant cases. The effects described can also occur simultaneously.

Example 1: Over-demand

The following example shows over-demand when the reservation function is not activated.

Initial situation:

- A picking order without automatic identifier assignment was created for a lot-managed item

- Quantity: 100 kg

- Sufficient inventory is available

- The following quantities in the Open column represent the open issue quantitiess that are displayed in the Availability query application

- Picking order generated:

| Identifier | Open |

| 100 kg |

- 40 kg of lot LOT1 reported:

| Identifier | Open |

| 60 kg | |

| LOT1 | 40 kg |

- 80 kg of lot LOT2 reported:

| Identifier | Open | Comment |

| 0 kg | 20 kg are over-demands due to the over-reported LOT2 value. | |

| LOT1 | 40 kg | |

| LOT2 | 80 kg |

- The quantity of batch LOT2 reduced to 70 kg:

| Identifier | Open | Comment |

| 10 kg | 20 kg remain as over-demands. These are visible as an open quantity at both identifier and item level. The picking order cannot be completed in this state. No over-demands may arise at identifier level. Accordingly, an identifier quantity must be reduced. | |

| LOT1 | 40 kg | |

| LOT2 | 70 kg |

- The quantity of batch LOT2 reduced to 60 kg:

| Identifier | Open | Comment |

| 20 kg | 20 kg remain as over-demands. These are displayed as an open quantity. The picking order can be completed in this state. | |

| LOT1 | 40 kg | |

| LOT2 | 60 kg |

- Picking order completed:

| Identifier | Open | Comment |

| 0 kg | The over-demand was deleted when the pickign order was completed. | |

| LOT1 | 40 kg | |

| LOT2 | 60 kg |

Example 2: Over-demand with reservation

If the Reservations function is used, reservations are created for reporting quantities. Over-demands are also reserved if there is sufficient inventory. This reservation is removed together with the over-demand when the picking order is completed.

Initial situation:

- A picking order without automatic identifier assignment was created for a lot-managed item

- Quantity: 100 kg

- Sufficient inventory is available

- The following quantities in the Open column represent the open quantities that are displayed in the Availability query application

- Picking order generated:

| Identifier | Open | Reserved |

| 100 kg | 100 kg |

- 40 kg of lot LOT1 reported:

| Identifier | Open | Reserved |

| 60 kg | 60 kg | |

| LOT1 | 40 kg | 40 kg |

- 80 kg of lot LOT2 reported:

| Identifier | Open | Reserved | Comment |

| 0 kg | 0 kg | 20 kg have arisen as over-demands due to the LOT2 value being reported too high. Inventory was also reserved for the over-demand, so that it is not available for other processes. | |

| LOT1 | 40 kg | 40 kg | |

| LOT2 | 80 kg | 80 kg |

- The quantity of lot LOT2 reduced to 70 kg:

| Identifier | Open | Reserved | Comment |

| 10 kg | 10 kg | 20 kg remain as over-demands. These are visible as an open quantity at both identifier and item level. Identifeir has also been reserved for over-demands so that it is not available for other uses.

The picking order cannot be completed in this state. There must be no over-demand at identifier level. Accordingly, an identifier quantity must be reduced. |

|

| LOT1 | 40 kg | 40 kg | |

| LOT2 | 70 kg | 70 kg |

- The quantity of batch LOT2 reduced to 60 kg:

| Identifier | Open | Reserved | Comment |

| 20 kg | 20 kg | 20 kg remain as over-demands. These are visible as an open quantity at item level. Inventory has also been reserved for over-demands so that it is not available for other processes.

The picking order can be completed in this state. |

|

| LOT1 | 40 kg | 40 kg | |

| LOT2 | 60 kg | 60 kg |

- Picking order completed:

| Identifier | Open | Reserved | Comment |

| 0 kg | 0 kg | The over-demand was deleted when the picking order was completed. The associated reservation was also deleted. | |

| LOT1 | 40 kg | 40 kg | |

| LOT2 | 60 kg | 60 kg |

Example 3 Over-demand without reservation

If an identifier is entered in the reporting that does not have sufficient available inventory and therefore cannot be reserved, the reporting is accepted, but such a picking order cannot be completed. In this case, either a different identifier should be entered or the quantity should be adjusted.

Initial situation:

- A picking order without automatic identifier assignment was created for a lot-managed item

- Quantity: 100 kg

- Existing situation:

- Sufficient inventory is available for lot LOT1

- An inventory of 10 kg is available for lot LOT2

- An inventory of 50 kg is available for lot LOT3

- The following quantities in the Open column represent the open quantities that are displayed in the Availability query application

- Picking order generated:

| Identifier | Open | Reserved |

| 100 kg | 100 kg |

- 40 kg of lot LOT1 reported:

| Identifier | Open | Reserved |

| 60 kg | 60 kg | |

| LOT1 | 40 kg | 40 kg |

- 80 kg of lot LOT2 reported:

| Identifier | Open | Reserved | Comment |

| 50 kg | 50 kg | Initially, an over-demand of 20 kg arises due to the reporting of 80 kg at identifier level.

In addition, there is over-demand based on the reservations: Reservations must not be lost due to the reporting of insufficient inventory at identifier level. For this reason, 10 kg are reserved at identifier level (LOT2) and 50 kg at item level. This results in an open demand of 50 kg at item level (see column Open). This results in a total over-demand of 70 kg. |

|

| LOT1 | 40 kg | 40 kg | |

| LOT2 | 80 kg | 10 kg |

- The quantity of batch LOT2 reduced to 10 kg:

| Identifier | Open | Reserved | Comment |

| 50 kg | 50 kg | By reducing the lot LOT2 to 10 kg, the open quantity at item level is increased by 70 kg to 120 kg. Of these, 50 kg are already reserved, leaving an over-demand of 70 kg. These 70 kg are deleted immediately so that they are not reserved. | |

| LOT1 | 40 kg | 40 kg | |

| LOT2 | 10 kg | 10 kg |

- 50 kg of lot LOT3 reported:

| Identifier | Open | Reserved | Comment |

| 0 kg | 0 kg | The picking order can be completed in this state. | |

| LOT1 | 40 kg | 40 kg | |

| LOT2 | 10 kg | 10 kg | |

| LOT3 | 50 kg | 50 kg |

- Picking order completed:

| Identifier | Open | Reserved |

| 0 kg | 0 kg | |

| LOT1 | 40 kg | 40 kg |

| LOT2 | 10 kg | 10 kg |

| LOT3 | 50 kg | 50 kg |

Automatic identifier assignment

Automatic identifier assignment refers to the assignment of an identifier to an item in an order line item by the system. The system reserves the required quantity of the identifier at the relevant warehouse and assigns it to the order.

The automatic identifier assignment takes place depending on the order type used. In the following order types, you can specify whether an identifier assignment should take place when the respective order is created:

- Delivery order type

- Picking order type

The automatic identifier assignment can be defined in these two order types via a corresponding entry in the Identifier assignment selection field. Possible values are:

- Yes – activates the automatic identifier assignment.

- Only in unstructured warehouses – activates the automatic identifier assignment only for picking orders or deliveries from unstructured warehouses.

- No – deactivates the automatic identifier assignment.

The field in the delivery order type controls the identifier assignment when creating the delivery orders, regardless of whether a picking order is created or not. The field in the picking order type only controls the identifier assignment when creating picking orders from production. An identifier assignment when creating a picking order from an existing delivery order is not supported.

If the automatic identifier assignment is deactivated in both order types, the identifier assignment only takes place when the inventory orders are created in subdivided warehouses. In the inventory order type, the identifier assignment is therefore always implicitly activated, even if no corresponding input field is displayed in the Inventory order types application. If the warehouse at which picking takes place is not subdivided into storage locations, no automatic identifier assignment takes place in this case.

If the automatic assignment of identifiers already takes place at a subdivided warehouse when the picking order or delivery order is created, the assigned identifiers are taken into account when the inventory orders are created. As inventory order creation also takes into account the information relevant to the storage location, it is possible that no inventory orders can be created for the assigned identifiers. This is the case, for example, if an identifier is assigned when the order is created that is located in a warehouse zone that is excluded by the withdrawal restriction used. For this reason, it is recommended to use the value Only in unstructured warehouses instead of Yes for the identifier assignment.

Further information can be found in the articles Introduction: Reservations and Identifier reservations.

FIFO date

In all withdrawal strategies, the item inventories are determined according to their FIFO date. In FIFO, the inventory that is put away first is also removed first.

The FIFO date is managed on a daily basis for each item inventory. How the FIFO date is calculated depends on whether the item is managed in identifiers or in which identifier it is managed:

- For items that are not managed in identifiers, the putaway date is used as the FIFO date.

The putaway date indicates when the inventory record was created. An inventory record is typically created with the first receipt or the first storage location reservation. In the case of replenishment of partial quantities with a single mark, the inventory put away adopts the putaway date from the inventory already put away. If the storage unit is replenished with another item or another identifier, a new inventory record is created and the replenished inventory is given its own putaway date. - For items that are managed in lots or serial numbers, the entry date of the identifier is used as the FIFO date.

- The expiration date (Exp. date) of the batch is used for batch items. If the expiration date is changed for a specific batch in the identifier master data, the FIFO dates in storage location inventories are adjusted. Please also read Automatic identifier assignment of batches to find out which other factors are taken into account when assigning identifiers to batches.

If two identifiers have the same FIFO date, the identifiers of the storage strategy used, such as the withdrawal sorting, decide which one is determined first. If all influencing factors are the same, the identifiers are assigned in alphabetical order.

In the article Introduction: Storage strategies, you will find a description of the effect of storage strategies at warehouses that are divided into storage locations.

Automatic identifier assignment of lots

The automatic identifier assignment of items that are managed in lots takes place according to the entry date of the respective lot.

Automatic identifier assignment of batches

The automatic identifier assignment of items that are managed in batches is based on the expiration date of the respective batch.

The following conditions must be met for a batch to be taken into account in the automatic identifier assignment:

- Unreserved inventory from the batch is available at the warehouse

- The quality status (QA status) of the batch has the value Released

- The retaining date of the batch has already passed

- The expiration (exp. date) of the batch has not yet been reached

- The time until the expiration date is reached is longer than the minimum batch lifetime (only applies to sales processes)

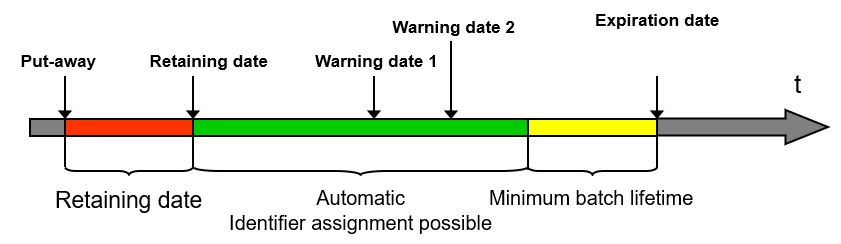

If one of the above conditions does not apply, the identifier is not assigned. The following illustration shows the significance of the retaining date, expiration date and minimum batch life when automatically assigning identifiers to batches.

During the retaining period (red), automatic identifier assignment is generally not possible. The minimum batch life (yellow) is stored in the item master data, but can also be defined on a customer-specific basis.

The following sections explain the batch identifiers relevant for the automatic assignment of identifiers.

Retaining period

The retaining period is the period between putaway and the time at which the batch is available for withdrawal. Quality checks, for example, can take place during the retaining period.

When entering a batch, the current date is added to the retaining period stored in the item master data and displayed as the default value.

Minimum batch life

The minimum batch life is the period of time that must still be available until the expiration date for the batch to be taken into account in the automatic identifier assignment.

The minimum batch life is stored in the item master data, but can also be defined on a customer-specific basis. The minimum batch life is taken into account for sales processes during the automatic identifier assignment that takes place when inventory orders are created. The minimum batch life is not taken into account for the automatic identifier assignment that does not take place for sales processes, e.g. inventory orders from a warehouse requisition.

Expiration date

Only batches that are within the period from the retaining date to the expiration date minus any minimum batch life for sales processes on the day of the identifier assignment are taken into account in the automatic identifier assignment. All other batches (expired or still in the retaining period) are not taken into account.

The following example illustrates the significance of the use-by date, expiration date and minimum batch life when automatically assigning identifiers to batches. The example is based on a batch with a expiration date of December 5 and a expiration date of December 13. The minimum batch life is 5 days.

| Day | Retaining date | Minimum batch life | Exp. date | Automatic assignment |

| Dec. 01. | Not achieved | Not achieved | Not achieved | Not possible |

| Dec. 02. | Not achieved | Not achieved | Not achieved | Not possible |

| Dec. 03. | Not achieved | Not achieved | Not achieved | Not possible |

| Dec. 04. | Not achieved | Not achieved | Not achieved | Not possible |

| Dec. 05. | Achieved | Not achieved | Not achieved | Possible |

| Dec. 06. | Achieved | Not achieved | Not achieved | Possible |

| Dec 07. | Achieved | Not achieved | Not achieved | Possible |

| Dec. 08. | Achieved | Achieved | Not achieved | Not possible |

| Dec. 09. | Achieved | Achieved | Not achieved | Not possible |

| Dec. 10. | Achieved | Achieved | Not achieved | Not possible |

| Dec. 11. | Achieved | Achieved | Not achieved | Not possible |

| Dec. 12. | Achieved | Achieved | Not achieved | Not possible |

| Dec. 13. | Achieved | Achieved | Achieved | Not possible |

| Dec. 14. | Achieved | Achieved | Achieved | Not possible |

| Dec. 15. | Achieved | Achieved | Achieved | Not possible |

Batch splitting

If no identifier is specified in the order line item, the following two automatic assignment options are used. Which one is used depends on the setting for the Batch splitting function in the item master data.

- Batch splitting function is activated:

The total quantity of the item to be picked can be supplied from several different identifiers.

- Function Batch splitting function is deactivated:

The total quantity of the item to be picked must be supplied from a single identifier.

For warehouses that are not divided into storage locations, the automatically assigned identifiers can still be changed in the Picking orders application. However, the automatic identifier assignment by the inventory order does not take into account whether batch splitting is permitted. If batch splitting is not permitted, the system checks whether there is only one batch per delivery order line item when the picking order is completed. If this is not the case, the picking order cannot be completed. If the inventory order has reported different identifiers for a picking order like item that lead to a batch split for a delivery order line item, the picking order may have to be canceled and a new picking order created.

Automatic identifier assignment of serial numbers with inventory management

The automatic identifier assignment of items that are managed in serial numbers with inventory management is carried out according to the entry date of the serial number. The oldest serial number on a storage unit determines the FIFO date of the entire storage unit. For batches and lots, on the other hand, the FIFO date is managed per identifier on the storage unit.

Inventory-managed serial numbers are assigned to the inventory order line items depending on the setting in the Customizing application, Inventory management function. In the field Serial numbers assignment in inventory order field, the following settings are possible:

- Do not assign:

The serial numbers determined by the putaway or withdrawal logic are not assigned to the inventory order line items. The item appears in its total quantity in the inventory order line item. The serial numbers must be added manually to the inventory order line items in the inventory order using a separate action. During reporting, the added serial numbers are reported to the upstream voucher.

- Assign:

The serial numbers determined by the putaway or withdrawal logic are assigned to the inventory order line items. The inventory order item receives the determined serial numbers as default values, which can be changed manually.

During putaway, the opening method of the identifier in the item master data takes precedence over the settings in the Customizing application. If the opening method Automatic has been defined as the default value for the identifier in the item master data, the inventory-managed serial numbers are always assigned to the inventory order. For items managed in serial numbers, only automatic opening is permitted in the item master data. Therefore, serial numbers managed in inventory are always assigned to inventory orders.

Normally, the assignment of inventory-managed serial numbers to inventory orders is recommended. However, if the serial numbers are automatically generated during reporting using a reader or the items managed in serial numbers are mainly moved in small quantities, then the Do not assign setting may be advantageous.