Topic overview

The available inventory designates the forecast inventory of an item on a future date. The availability is calculated on the basis of an availability rule and consists of the current inventory plus the planned receipts and issues as well an any back orders.

If you have activated the Reservations function in Customizing, the available inventory is defined as the forecast, unreserved inventory of an item on a future date.

The availability of an item is taken into consideration by various processes in Comarch ERP Enterprise. For example, an availability check can be performed when a sales order is created or when a production order is dispatched. The availability of any inventory item can be queried and displayed in the Inventory Management framework.

This document explains how availability is calculated and describes the effect of the availability rule on the query result. The applications used and the related fields, actions, and procedures are described in separate documents.

Definitions of terms

Identifiers

An identifier enables the identification of specific items or item variants. Comarch ERP Enterprise supports batch, lot, and serial number identifiers, for example.

Inventory

The inventory is the quantity of an item, in the displayed storage unit, that is currently available at a warehouse.

Blocked inventory

Blocked inventory is inventory of an item with the Blocked quality status. Blocked inventory usually comes about when the user of an identifier has assigned the Blocked quality status. It can also come about when inventory of an item is put away in a warehouse zone with the Blocked quality status. In the availability rule it can be specifies whether blocked inventory should be considered as available for the availability check.

Warehouses

A warehouse is a logically or physically defined area in which item inventory is maintained. A warehouse is always assigned to a site. A warehouse can be subdivided into storage locations if storage location control is enabled in Customizing. The exact structure of the warehouse is defined by the warehouse organization.

Expiration date

The expiration date is the date up to which the usability of a batch is guaranteed. After the expiration date, the lot is not considered for withdrawal. The expiration date of a batch must be specified.

Quarantined inventory

Quarantined inventory is inventory of an item with the In quarantine QA status. These items are usually rechecked and then possibly blocked. The In quarantine QA status is usually assigned by the user. The system generates this status if the item is put away in a quarantine storage location.

Back orders

Back orders are order line items with open quantities for delivery whose delivery date lies in the past (i.e., is smaller than the current date).

Availability

The availability is the predicted supply of an item on a current or a future date. Availability is calculated by means of an availability rule and consists of:

- the current inventory,

- planned receipts,

- the planned issues.

Possible back orders can also be taken into account with the calculation of availability. If the reservation function is used, availability consists of:

- the unreserved current inventory,

- the unreserved planned receipts, and

- the unreserved planned issues.

Partial quantities are also taken into consideration in the process.

Availability rules

The availability rule governs the determination and display processes of an inventory’s availability. With the aid of an availability rule, it is determined per relevant voucher type with what status the availability check is to consider the respective order line item. An availability rule also specifies whether blocked or quarantined inventory should be taken into account and whether the replenishment lead time should be considered.

Quality status (QA status)

A quality status or quality assurance status (QA status) can be defined for the warehouse and warehouse zone levels, and in parallel also for the identifier level. Inventory can be analyzed and utilized specifically according to QA status. If QA status is defined for certain inventory both at the warehouse level and for the identifier level, the inventory has the lower QA status.

Overview

The available inventory is calculated from the current inventory and planned receipts and issues. The following receipts and issues are examined in Comarch ERP Enterprise:

| Receipt/issue | Role | Date |

| Sales quotation | Issue | Shipping date |

| Sales order | Typically: issue; if the quantity is negative: receipt | Shipping date |

| Delivery order | Issue | Voucher date |

| Picking order (from production only) | Issue | Voucher date |

| Distribution order | Source warehouse: issue; destination warehouse: receipt | Source warehouse: shipping date; destination warehouse: delivery date |

| Production order | Production order header: receipt Material line item: issue Co-product: receipt Material provided to vendor: issue |

Production order header: current end or latest end Material line item: current begin Co-product: current end or latest end plus transition time Material provided to vendor: current begin |

| Purchase order | Typically: receipt; customer return: issue | Receipt: delivery date; customer return: date of return |

| Inventory requisition | Withdrawal: issue; put-away: receipt; relocation: issue on source side, receipt on destination side | Creation date |

| Inventory posting | Not yet processed inventory postings with the quantity transaction: issue or receipt, depending on the resulting inventory change | Posting date |

| Incorrect inventory posting | Issue or receipt or both (transfer postings), depending on the resulting inventory change | Posting date |

| Voucherless demand | Issue | Generation date |

| Batch inventory | Start of hold time: issue End of hold time: receipt Start of minimum batch lifetime: issue Batch expiration: issue (see Availability records for batch inventories) |

Start of hold time: not specified End of hold time: retaining date + 1 calendar day Start of minimum batch lifetime: expiration date – remaining shelf life Batch expiration: expiration date |

Other vouchers or orders do not count as planned receipts or issues because, for example, like customer contracts they are only a preliminary step for plannable sales orders or like receipts of goods they have no additional value for the availability calculation.

Availability records

Uniform data, called availability records, are generated for all availability-relevant vouchers, orders, and other participants in order to simplify the calculation and make it efficient. An availability record describes a planned change in the inventory of an owner, an item, and, if applicable, a specific identifier at a warehouse on an exact date.

These records are adapted appropriately for each relevant change. For example, if the quantity or delivery date changes on a purchase order line item, upon saving these changes are transferred to the availability record that was generated for this purchase order line item.

If necessary, the changes will be transferred to availability records even while editing is taking place (see section Temporary availability rules).

These availability records are displayed cumulatively in the Item and Identifier views of the Availability query application. The individual availability records are displayed in order of date in the Origin view.

Reservations

If the Reservations function is used, reserved quantities are taken into consideration in the availability calculation as follows:

- If the inventory is reserved, the reserved quantity is deducted from the total inventory at the outset.

- If a planned issue reserves the inventory or a planned receipt, its open (availability-relevant) quantity is reduced by the amount of the reserved quantity; accordingly, a completely reserved planned issue is always regarded as available.

- If a planned receipt is reserved by a planned issue, its open (availability-relevant) quantity is reduced by the amount of the reserved quantity.

Availability records for batch inventories

If there are no planned receipts or issues for an inventory item and the inventory is always greater than zero, this inventory is completely available on the current date or on any future date.

An exception to this is items managed by batch. Batches have additional properties that, in reality, affect the availability of inventory on the time axis: retaining date, minimum batch lifetime, and expiration date. These properties affect the inventory as follows:

- The inventory of a batch during the retaining term is not yet available. Because the retaining date is interpreted as the last day of the retaining term, an entered retaining date influences the availability as combination of a planned issue whose scheduled date falls before all other planned issues (the actual existing inventory is not yet available) and a planned receipt on the retaining date plus one calendar day (inventory is Released from the retaining term)

- The inventory of a batch during the remaining shelf life is no longer available. This must be set equal to a planned issued on the expiration date minus the minimum batch lifetime.

- If a minimum batch lifetime is not defined, the inventory of a batch is no longer available starting from the expiration date, which is equivalent to a planned issue on the expiration date.

In order for these properties to be used for the availability check, real availability records are created for these effective availability changes and are maintained with every inventory change. An exception is the remaining shelf life, which is taken into consideration dynamically and according to context. For sales vouchers, the remaining shelf life is calculated from the corresponding sales data for the item (dependent on organization, customer classification, or customer). For all other vouchers, the settings from Customizing are used for this calculation. The batch-specific availability records are also displayed in the Origin view of the Availability query application.

Availability records for batch inventories are considered separately in the availability check. The reduction of the availability record on the expiration date is variable and depends on previous planned issues: the remaining inventory that is still available on the expiration date is no longer available. The same applies to the availability record at the beginning of the remaining shelf life. However, batch-specific availability records around the retaining term are constant.

Since batches within the retaining term or after the expiration date are undeliverable, the reservations on item level are not subtracted from the very first. Instead, they are assigned to the batches that are deliverable at the respective points in time.

Further information can be found the section Examples for batches.

Processes and applications

The availability is taken into consideration in the following processes and applications, among other places:

- Purchasing

The availability is considered in the Calculate purchasing recommendations and Calculate distribution recommendations applications.

- Sales

The availability check is used when a line item is created or changed in a sales quotation, sales order, or distribution order to determine whether the desired quantity of an item is available at the specified warehouse on the shipping date.

- Production

The availability check occurs when production orders are dispatched but can also be performed manually in the Production orders or Production cockpit application. Once dispatched, item inventories are excluded from the availability. For co-products, a completion deadline can be specified for the item in the production order. This deadline is regarded as a planned receipt in the availability query.

- Inventory Management

In the Availability query application, it is possible to query the availability of any particular inventory item on any particular date.

The following documents describe how the availability is taken into consideration in the respective applications:

- Purchasing recommendation calculation

- Distribution recommendation calculation

- Availability check

- Introduction: Production

- Availability query

Data model

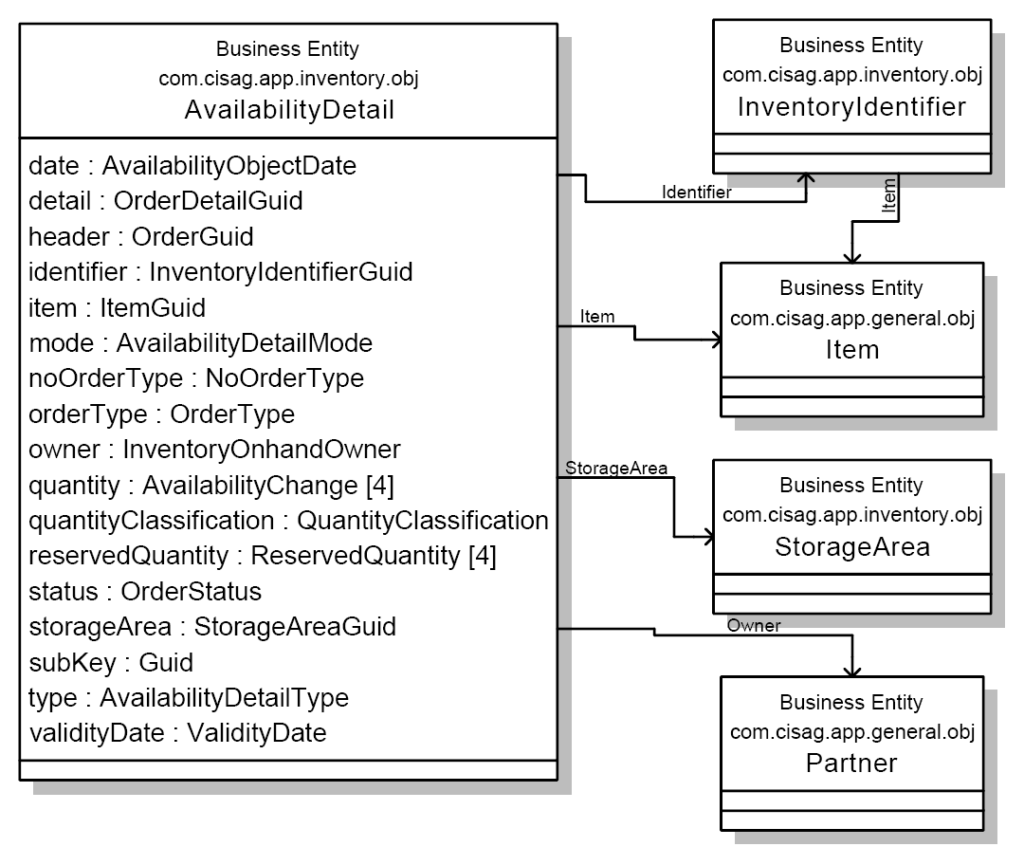

The availability calculation is based on the current inventory as well as the availability records in the business entity com.cisag.app.inventory.obj.AvailabilityDetail. The following figure shows some of the most important attributes of the availability records as well as the relationships to other business entities.

The

The detail and header attributes are used to link the availability record to the triggering order. The subKey attribute is also part of the primary key. Consequently, availability records of different warehouses or identifiers can be generated for the same order line item. This is necessary, for example, when a sales order line item with batch splitting is picked.

If a new order line item is created, a new availability record is generated. If an existing order line item is changed, modified data are added to the availability record. If an order line item is deleted, the quantity in the availability record is then set to zero. Thus, the sum of all availability records for an order line item always reflects the current line item quantity. Multiple availability records for each order line item can therefore be displayed in the Origin view of the Availability query application.

Temporary availability records

The availability records in the business entity com.cisag.app.inventory.obj.AvailabilityDetail can be provided with a limited validity period in the validityDate attribute. These temporary availability records are used in order to include consideration of order line items that have been created but not yet saved as well as changes to existing order line items when calculating availability.

A temporary availability record is generated immediately when, for example, a new sales order line item is accepted from the line item editor. The temporary availability record is converted to an availability record with unlimited validity period when the sales order line item is first saved. If the sales order is discarded before the sales order line item has been saved, the temporary availability record will be deleted. Depending on the validity period, it is possible that the validity of the temporary availability record will end before the sales order line item has been saved. To ensure the most accurate availability query possible in this case, the validity period will be reset if an action, such as a check, is repeated in the line item editor.

The validity period of temporary availability records can be entered in the Inventories function under the Inventory management main function of the Customizing application.

Availability rules

The availability rule specifies the order types and voucher line item status for which planned issues and receipts as well as back orders are considered when calculating availability. The following order types can be entered in the availability rule:

- Sales quotation

- Sales order

- Production order

- Inventory requisition

- Purchase order

- Distribution order

- Picking order

- Delivery order

The availability rule also specifies other criteria of the availability query, such as which quality assurance statuses are taken into consideration and whether or not the replenishment lead time is used in the calculation.

Multiple availability rules can be defined. Different availability rules can be used in different processes. For example, the availability calculation within the purchasing recommendation can use a different rule than the availability check within a sales order.

If an availability rule is not specified for the availability calculation, the availability rule stored in the Customizing application will be used. If an availability rule is not stored there for the site, then the availability rule stored for the active OLTP client is used.

For a description of the Availability rules application, see the Availability rules article.

Calculations

The objective of the availability calculation is to calculate the available item quantity on a certain date. The availability consists of the current inventory plus the planned receipts and minus the planned issues up until and including the By date. Any order line items with quantities open for delivery, whose delivery date lies in the past can also be considered in the calculation. These open quantities are also designated as back orders.

This calculation is dynamic; thus, the result changes every time there is a change in the availability-relevant data.

The availability is calculated according to the following method:

- The current inventory is determined.

- Inventories with quality assurance status Blocked and In quarantine are deducted from the current inventory, according to the availability rule used.

- The planned receipts with a delivery date up until and including the By date of orders whose order category and status are taken into consideration by the availability rule are determined and added to the current inventory.

- The planned issues with a delivery date up until and including the By date of orders whose order category and status are taken into consideration by the availability rule are determined and subtracted from the current inventory.

- The back orders with a delivery date in the past of orders whose order category and status are taken into consideration by the availability rule are determined and added to or subtracted from the current inventory.

If you have activated the Reservations customizing function, the respective quantities are reduced by the amount of the reserved quantities. See also the examples in the section Example with reservations.

The following information is not taken into consideration when calculating the availability:

- Binding period

The binding period for sales quotations is not considered. To ensure that expired sales quotations do not affect the availability you can, for example, complete old sales quotation line items or deactivate the consideration of past due sales quotations in the availability rule.

- Contracts

Neither customer contracts nor supplier contracts are considered.

- Supplier quotations

Only the planned receipts and issues from the order types specified in the availability rule are considered. Planned receipts and issues from other order types, e.g., from supplier quotations, are not considered in the calculation.

- Minimum inventory level and reorder level

The minimum inventory level and reorder level of items are not considered. That is, the total inventory calculated by the query is regarded as available regardless of any minimum inventory level.

Example without reservations

An item has an inventory of 100 pcs, and the following planned issues and receipts exist:

- A sales order line item VA1 on December 5 with a quantity of 80 pcs.

- A purchase order line item BA1 on December 10 with a quantity of 50 pcs.

- A sales order line item VA2 on December 15 with a quantity of 100 pcs.

These data are represented as follows in the Origin view of the Availability query application:

| Inventory/order | Date | Open | Available |

| Inventory | 100 pcs | ||

| Sales order VA1 | December 5 | -80 pcs | 20 pcs |

| Purchase order BA1 | December 10 | 50 pcs | 70 pcs |

| Sales order VA2 | December 15 | -100 pcs | -30 pcs |

The available quantity on a date is thus calculated on a running basis from the latest available quantity and the open receipt and issue quantities:

100 – 80 = 20, 20 + 50 = 70, 70 – 100 = -30.

This representation reveals that 100 pcs will be available on a date prior to December 5, 70 pcs on a date between December 5 and December 10, and -30 pcs on a date after December 15 (shortage on December 15 in the amount of 30 pcs).

If a new sales order line item VA3 is now created on December 1 with a quantity of 30 pcs, this means that the sales order VA1 is no longer deliverable because the shortage of 10 pcs occurs already on December 5:

| Inventory/order | Date | Open | Available |

| Inventory | 100 pcs | ||

| Sales order VA3 | December 1 | -30 pcs | 70 pcs |

| Sales order VA1 | December 5 | -80 pcs | -10 pcs |

| Purchase order BA1 | December 10 | 50 pcs | 40 pcs |

| Sales order VA2 | December 15 | -100 pcs | -60 pcs |

Example with reservations

If you have activated the Reservations customizing function, an additional factor comes into play.

For the example in section Example without reservations reservations are required for the examined item and the sales order type provides for an automatic reservation without reservation term.

In this case, the line item VA1 would be completely reserved from the inventory and line item VA2 would be partially reserved from the inventory (assuming VA2 was saved after VA1):

| Inventory/order | Date | Open | Reserved inventory | Available |

| Inventory | 100 pcs | 100 pcs | 0 pcs | |

| Sales order VA1 | December 5 | -80 pcs | 80 pcs | 0 pcs |

| Purchase order BA1 | December 10 | 50 pcs | 50 pcs | |

| Sales order VA2 | December 15 | -100 pcs | 20 pcs | -30 pcs |

Here, the available quantity on a date is calculated on a running basis from the latest available quantity and the open unreserved receipt and issue quantities:

100 – 100 = 0, 0 – 80 + 80 = 0, 0 + 50 = 50, 50 – 100 + 20 = -30.

According to this representation, there is no available quantity on a date prior to December 10. The total inventory is assigned in a binding manner to the two sales order line items. The inventory is thus no longer available for other orders.

If a new sales order line item VA3 is now created on December 1 with a quantity of 30 pcs, this means that the sales order VA1 remains deliverable for now; the shortage of 30 pcs occurs on December 1:

| Inventory/order | Date | Open | Reserved inventory | Available |

| Inventory | 100 pcs | 100 pcs | 0 pcs | |

| Sales order VA3 | December 1 | -30 pcs | -30 pcs | |

| Sales order VA1 | December 5 | -80 pcs | 80 pcs | -30 pcs |

| Purchase order BA1 | December 10 | 50 pcs | 20 pcs | |

| Sales order VA2 | December 15 | -100 pcs | 20 pcs | -60 pcs |

If also planned receipts can be reserved for the examined item, the following pattern is produced (without VA3):

| Inventory/order | Date | Open | Reserved inventory | Reserved receipt | Available |

| Inventory | 100 pcs | 100 pcs | 0 pcs | ||

| Sales order VA1 | December 5 | -80 pcs | 80 pcs | 0 pcs | |

| Purchase order BA1 | December 10 | 50 pcs | 50 pcs | 0 pcs | |

| Sales order VA2 | December 15 | -100 pcs | 20 pcs | 50 pcs | -30 pcs |

Here, the available quantity on a date is also calculated on a running basis from the latest available quantity and the open unreserved receipt and issue quantities:

100 – 100 = 0, 0 – 80 + 80 = 0, 0 + 50 – 50 = 0, 0 – 100 + 20 + 50 = –30.

On a date between December 10 and December 15, there is also no available inventory this time (in contrast to the situation where only inventories can be reserved), because the purchase order line item BA1 is completely reserved by the sales order line item VA2. As soon as the receipt of goods for BA1 is posted, the receipt reservation is converted to an inventory reservation and from then on VA2 has only an inventory reservation in the amount of 70 pcs.

Example for batches

An item managed by batch has an inventory of 100pcs, comprising one single batch (no retaining term, expiration date=December 20). In addition, a sales order line item VA1 for September 10 with a quantity of 80 pcs exists (without batch specification and without reservation).

In the Origin view of the Availability query application, the data are displayed as follows:

| Inventory/order | Due date | Open | Available |

| Inventory | 100 pcs | ||

| Sales order VA1 | September 10 | -80 pcs | 20 pcs |

| (Expiration date) | December 20 | -20 pcs | 0 pcs |

On December 20 the remaining quantity of 20 pcs expires, leading to an availability of 0 pcs. The planned issue on the expiration date corresponds to the remaining quantity on that day and it is calculated dynamically. Planned issues on item level are assigned to specific batches during the availability calculation, which allows a realistic forecast of the availability reduction on the expiration date.

If the item is reserved automatically and a sales order line item VA2 is created for December 30 with a quantity of 10 pcs (without batch specification, completely reserved), then the following pattern is produced:

| Inventory/order | Due date | Open | Reserved inventory | Available |

| Inventory | 100 pcs | 90 pcs | 10 pcs | |

| Sales order VA1 | December 5 | -80 pcs | 80 pcs | 10 pcs |

| (Expiration date) | December 20 | -20 pcs | -10 pcs | |

| Sales order VA2 | December 30 | -10 pcs | 10 pcs | -10 pcs |

On December 30, the sales order line item VA2 is undeliverable, because the only batch is undeliverable on that day.

Consistent availability in processes

Business processes that influence availability are designed such that each participating order or voucher is responsible for its availability data. With the movement in the business process, availability data are transferred over and over until they become actual inventory changes in the inventory management server.

We will examine this activity using an example of a simple sales process. The tabular representation according to the individual process steps corresponds in general to the display in the Origin view of the Availability query application.

Starting point: Inventory of an item is 20 kg

- A new sales order line item with this item was saved on December 5 with a quantity of 15 kg:

| Inventory/order | Date | Open | Available |

| Inventory | 20 kg | ||

| Sales order | December 5 | -15 kg | 5 kg |

- On December 1, a sub-quantity (3 kg) is to be delivered to start. A delivery order is generated:

| Inventory/order | Date | Open | Available |

| Inventory | 20 kg | ||

| Delivery order | December 1 | -3 kg | 17 kg |

| Sales order | December 5 | -12 kg | 5 kg |

- A delivery slip is generated, which produces an inventory posting:

| Inventory/order | Date | Open | Available |

| Inventory | 20 kg | ||

| Inventory posting | December 1 | -3 kg | 17 kg |

| Sales order | December 5 | -12 kg | 5 kg |

- The inventory posting is processed by the inventory management server:

| Inventory/order | Date | Open | Available |

| Inventory | 17 kg | ||

| Sales order | December 5 | -12 kg | 5 kg |

The following applies in general: the order that occurs at the start of a business process changes the availability, while orders that arise during subsequent process steps do not change the availability. Depending on the process step, the reservations from the previous voucher are transferred to the following voucher instead (see also the available quantity on December 5 in the example above).

Time zones

The availability calculation is precise to the day. Within this calculation, planned issues are regarded as not available on the day of the issue. On the other hand, planned receipts are regarded as available starting on the day of the receipt. In a multi-site installation, the availability records may be produced in different time zones. For example, the availability records from purchase orders relate to the time zone of the respective purchasing organization and the availability records from sales orders relate to the time zone of the respective sales organization. In order to calculate the availability in a particular time zone context, an interval is initially defined that represents the day for this time zone. The interval spans 12 hours before and after the start of the By date, as shown in the following figure.

All availability records with a value in the date attribute that lies before or within the interval are taken into consideration when calculating the availability, irrespective of the particular time zone. Because all date information is saved with the time slice 00:00:00.000, the desired availability records can be calculated correctly in most cases. However, if the time zone of the examiner is more than 12 hours behind the time zone of the voucher-relevant organization, availability records with a date equal to the By date will not be considered.