Topic overview

By means of the inventory allocation, the allocable item inventory is distributed to order line items which are open for delivery. The allocation process considers delivery priorities, shipping dates, and delivery restrictions.

The inventory allocation is also available for materials required by production orders. If an item is both used as production material and sold directly, production orders and sales orders will compete for the inventory. A multi-site system additionally includes distribution orders.

Subsequently, you find general explanations on the inventory allocation, information about implementation options and the method as well as notes on the combination with reservations.

The Inventory allocation theme is relevant to the Calculate inventory allocation and Inventory allocation applications. These applications are described in the Calculate inventory allocation and Inventory allocation articles.

Processes

In the following, you will find the possible processes for distributing the allocable inventory to several sales, distribution, and production orders.

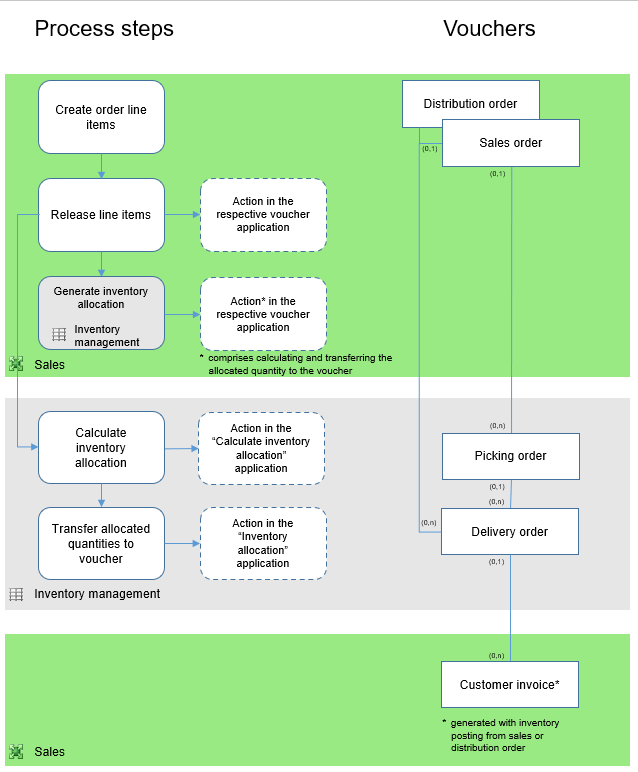

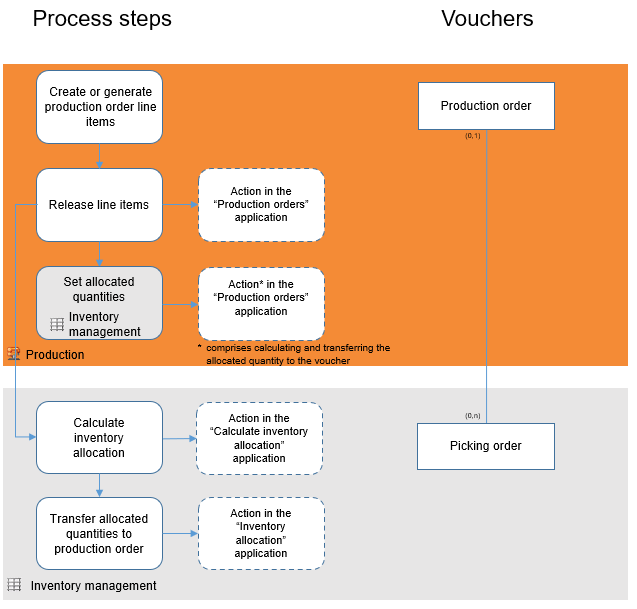

Process chart

Sales and distribution orders

Production orders

Process description

An inventory allocation can be performed as follows:

- By means of the [Generate inventory allocation] action in the relevant voucher application.

- By means of the Calculate inventory allocation and Inventory allocation applications.

Irrespective of the implementation method, inventory allocation is done as follows:

- Determining the relevant order line items.

- Calculating the allocable inventory.

- Quantity allocation to the relevant voucher.

The sales order type provides the information which allocated quantities are suggested for a sales order in the corresponding view of the line item table in the Sales orders application (delivery order/picking order, delivery or invoice with inventory posting). This setting is not required for distribution orders and production orders and therefore not to be defined.

The [Generate inventory allocation] action serves to both calculate the allocable quantity for the opened voucher and suggest the allocated quantity.

You can use the Calculate inventory allocation and Inventory allocation applications to distribute an allocable inventory to numerous vouchers.

If subsequent vouchers are created, any allocated quantities will be included in them: Instead of Open quantities, the Allocated quantities entered are used in the picking order, delivery order, and customer invoice, and are picked, delivered, or invoiced accordingly.

Preconditions

During the inventory allocation, only such order line items are included which meet the following conditions:

Sales or distribution line items

- have been released,

- have an open delivery quantity,

- have no allocated quantity,

- have Undelivered or Delivered in part as delivery status and No delivery order in process as delivery order status.

Besides, the setting for the used sales order type must indicate that an inventory allocation needs to be performed.

The production order line items

- have been released,

- have an open target quantity,

- have no allocated quantity,

- have Not reported or Reported in part as delivery status and No picking in process as picking status.

Furthermore, the setting for the used production order type must indicate that allocated quantities are utilized.

Perform inventory allocation

You can perform an inventory allocation for an individual sales, distribution, or production order or for several ones.

Inventory allocation for an individual voucher

If you want to assign allocable inventory to an individual voucher, use the [Generate inventory allocation] action in sales and distribution orders as well as the [Set allocated quantities] action in production orders.

Please also note the descriptions of the actions in the respective articles:

- Sales orders: Actions

- Distribution orders: Actions

- Production orders

Inventory allocation for several vouchers

Inventory allocations for several vouchers can be performed by means of the Calculate inventory allocation and Inventory allocation applications.

Calculate inventory allocation

The Calculate inventory allocation application is used both to determine the voucher line items to which inventory is to be allocated and to calculate the allocable inventory.

If the specifications for determining line items require that the allocable quantity is to be automatically transferred into the allocated quantity of the relevant vouchers, the inventory allocation will be completed after determination and calculation have been executed. The allocated quantities in the individual vouchers are defaults and thus can be changed.

If the allocated quantities are not automatically transferred, they will be available for further processing and transfer in the Inventory allocation application.

Inventory allocation

If the specifications for calculating inventory require that the allocable quantity is not to be transferred into the relevant vouchers, the suggested allocated quantity can be processed after having been calculated via the Inventory allocation application and transferred into the vouchers through another action.

Effects of delivery restrictions

If there is a delivery restriction for the sales or distribution order, the allocated quantities will only be allotted to the order line items if the allocable quantity is greater than or equal to the order quantity of the line item.

If the Deliver order in full restriction is set for the sales or distribution order, an automatic transfer into allocated quantities can only occur if all line items are completely allocated. Otherwise, all allocations for the order are automatically deleted.

If no automatic transfer into the allocated quantities is to take place, the allocated quantities will also remain unchanged if not all line items in the order can be delivered in full. You can change the allocated quantities manually and transfer them into vouchers via the Inventory allocation application.

Effects of delivery priorities

Delivery priorities only play a role when more open delivery quantities are available than allocable inventory.

Inventory allocation method

Inventory allocation is based on the following method:

- Calculating valid order line items according to selection and preconditions:

Order line items having reservations get allocated a quantity in the amount of the reserved inventory quantities in advance unless they are blocked. Unless the total order quantity has been reserved, the shortfall will be treated as any other line items.

- Calculating the allocable inventory:

| Allocable inventory | = | Current inventory |

| minus | planned issues from delivery orders | |

| minus | planned issues from picking orders for production | |

| minus | all allocated quantities entered in sales, distribution, and production orders, that pertain to the inventory allocation | |

| minus | the quantities of all inventory allocations already generated, whose quantities have not yet been transferred as allocated quantities into the sales/distribution and production orders |

If allocable inventory is available, it will be allocated to a line item in the corresponding amount. The inventory for line items with activated reservations is reserved through the inventory allocation.

During allocation, the allocation parameters are considered in the following order:

- Shipping date

- Delivery priority (0 to 9, with 0 being the highest priority)

- For parallel inventory units – the possible delivery quantity in the base unit is converted into the parallel inventory unit based on the estimated conversion factor.

- For packaging units – the possible delivery quantity is calculated in the base unit and will only be converted into the packaging unit if the result yields solely complete packaging units.

For some order line items, it can be defined that you have the possibility to access the inventory of several owners. The allocable inventory for such order line items is determined for each inventory owner individually. During allocation, the inventory owners are considered in the order specified in the order line item. It is possible to allocate the inventory of several inventory owners to one order line item.

Kit bills of material are allocated at the component level according to the allocable quantity of the scarcest component.

Interaction of reservations and inventory allocation

If automatic reservations are used for all items in all voucher applications, the inventory allocation can be omitted as follow-up processes can only be triggered if corresponding reservations exist.

If reservations are not used for all items or if the reservation is to be made manually in most cases, the inventory allocation and reservations will complement one another. As a result of the inventory allocation, the allocated quantities are reserved accordingly as well as transferred into the appropriate orders when the allocated quantities are entered in these orders. If the inventory allocation is discarded, the reservations generated by the inventory allocation will be released as well. However, quantities that were already reserved before the calculation of the inventory allocation are retained.

Special features in a multi-site environment

In a multi-site environment, distribution orders compete for existing inventory in addition to production orders and sales orders. Production orders, sales orders, and distribution orders are treated as equal by the Calculate inventory allocation application.

The inventory allocation includes the inventories of inventory owners designated in the orders (sales orders, production orders, and distribution orders) in the corresponding warehouse. Only such inventories are allocated whose owner matches the inventory owner in the order or – in case of several possible inventory owners – whose owner is included in the sequence of possible inventory owners.