In order to optimize generated material requirements recommendations, the algorithm used for creating them has been updated. The new algorithm refers to the following data defined in the system:

- Minimum inventory level – available in the Planning view (Planning data section) of the Items application. It allows you to define a minimum inventory level for a given item. If the item’s inventory level falls below the defined quantity, a material requirements recommendation will be generated.

- Target inventory level – available in the Planning view (Planning data section) of the Items application. It allows you to define a quantity to be reached upon each inventory replenishment. A target inventory level will be referred to if the inventory level falls below the minimum inventory level.

- Reorder level – available in the Planning view (Planning data section) of the Items application. It allows you to define an item’s inventory level below which a material requirements recommendation will be generated.

- Replenishment lead time – available in the Planning view (Purchasing data (external/internal) section) of the Items application. For purchasing items, you can determine the time from the moment of ordering to the moment of delivery. It will provide information to the Planning framework on when a given product would be available.

- Turnaround time – available in the Planning view (Production data section) of the Items application. It allows you to determine the production time of a production item. It will provide information to the Planning framework on when a given product would be available.

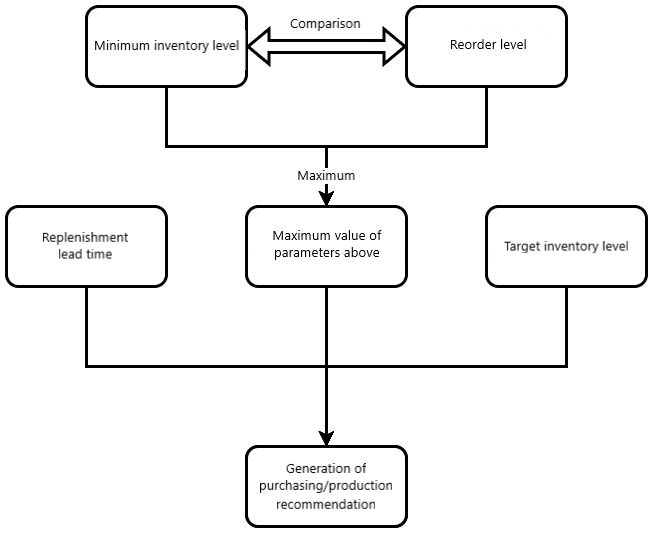

The diagram below visualizes the new planning algorithm:

The planning server calculates the expected inventory level of each item. This is the expected item quantity (planning, production, distribution, or purchasing recommendations are not taken into account) that will be available on a certain date. Next, the planning server compares expected quantities with the minimum inventory level and the reorder level of the item. Based on the greater of these two parameters, as well as the target inventory level and the demand coverage time, a demand coverage recommendation is created. This value can be greater because of an entered lot size.

The reorder level set as 0 is not taken into account by the planning algorithm.

The target inventory level set as 0 is not taken into account by the planning algorithm.

The reorder level should be greater than the minimum inventory level.

Example of use

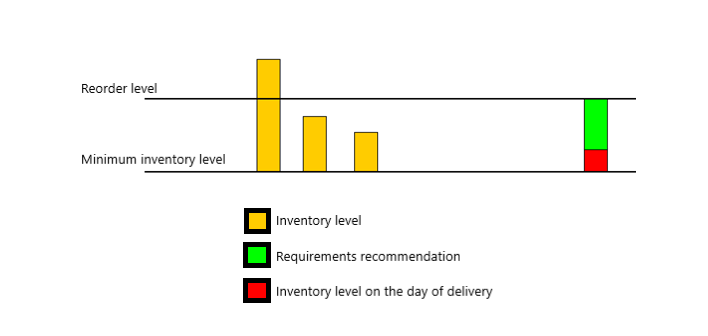

When the planning process is started, the inventory level is above the reorder level. During the time interval given, the inventory level will be reduced twice due to demand for the item arising in the system. Taking into account the replenishment lead time, the system, at the earliest possible time, will generate a requirements recommendation that will replenish the inventory level to the reorder level. If a lot size is defined for the item in the Planning view of the Items application, the ordered quantity may exceed the reorder level.