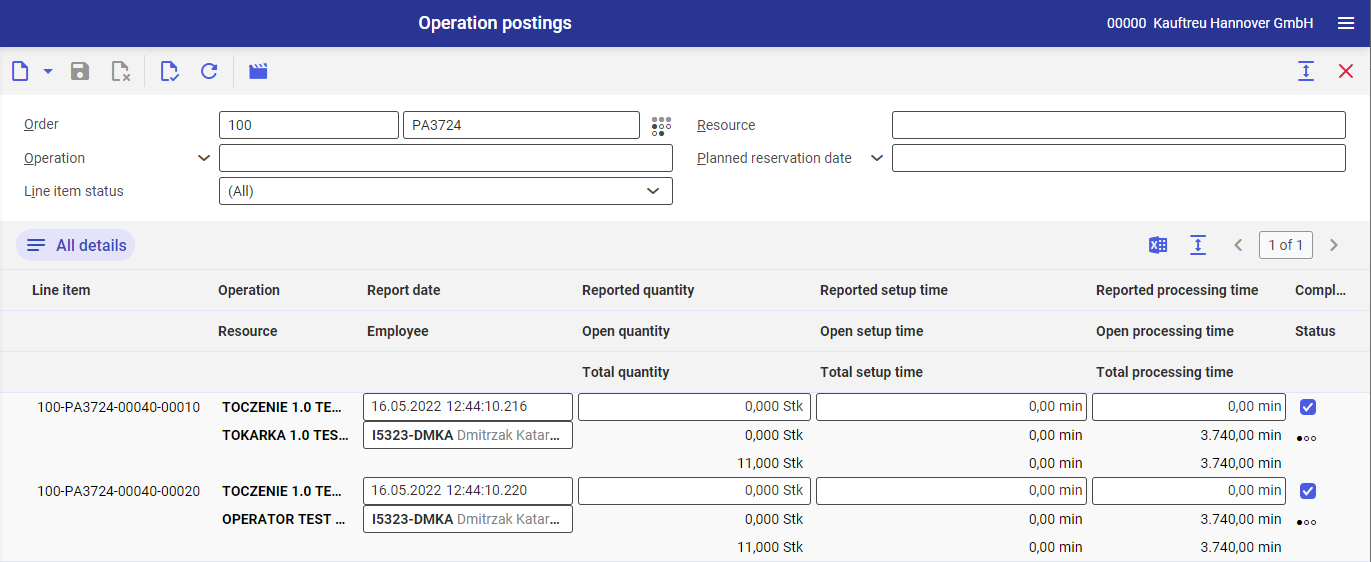

In Operation postings application you can enter data regarding operation posting processing, such as actual processing times and quantities processed by a production operation. The application consists of:

- Query pane – in this pane you can define specific operations to be approved.

- Work pane – in this pane you can enter the actual operation processing data.

Query pane

The application query pane is handled with the buttons below, next to the standard buttons, and contains the following fields:

- [New] – adds a new operation posting.

- [Post operation] – accepts the entered data and sends it to a production order.

- Order – this field is composed of two segments for entering the type and number of the production order for which production operations will be posted. If the defined production order data is loaded, its dot-like status is also displayed.

- Resource – in this field you can select the resources for which operations will be displayed in the work pane.

- Operation – in this field you can select production operations to be posted.

- Planned reservation date – in this field you can specify the date for which production operations will be posted in the work pane.

- Line item status – in this field you can filter data in the work pane by the following statuses:

- (All) – displays all operations, irrespective of their statuses.

- Not reported – displays unreported operations.

- Reported in part – displays partially reported operations.

- Reported in full – displays fully reported operations.

Hint

In order to refresh data in the application’s work pane table, a production order or operation or resource needs to be specified.

Note

Operations tagged as Automatic posting are not displayed.

Work pane

The work pane contains a table with the following buttons and columns:

- [All details] – displays additional table rows.

- [Output pages already displayed into file] – exports the table data to a file. The exported file format is XLS.

- Line item – displays a production order type/number/line item/sub line item.

- Operation – displays operation name.

- Resource – displays the name of the resource assigned to an operation.

- Report date (editable column) – you can enter an operation reporting date in this column.

- Employee (editable column) – you can enter an employee responsible for reporting an operation in this column.

- Reported quantity (editable column) – you can enter the actual number of pieces processed by operations.

- Open quantity – informs about the remaining quantity to be processed in order to complete the operation.

- Total quantity – additional column displayed upon selecting the [Target values] button. It presents the quantity suggested on the basis of bill of resources used in a given production order.

- Reported setup time (editable column) – you can enter the actual operation setup time.

- Open setup time – informs about the remaining setup time in a production order for a given operation.

- Total setup time – additional column displayed upon selecting the [Target values] button. It presents the quantity suggested on the basis of bill of resources used in a given production order.

- Reported processing time (editable column) – you can enter the actual operation duration in this column.

- Open processing time – informs about the remaining processing time to complete a given operation (if it is defined in the bill of resources).

- Total processing time – additional column displayed upon selecting the [Target values] button. It presents the quantity suggested on the basis of bill of resources used in a given production order.

- Completed (parameter) – if selected, it processes a line item and blocks its edition in the future.

- Status – displays the current operation status from the production order. Available statuses are:

- Reporting status – informs whether the operation-related activities have already been reported.

- Activity status – informs whether a given operation has started.

- Voucher output status – refers to a given production order operation.

Procedures: Operation posting

In order to post a production operation, follow the steps below:

- Open Operation postings

- Select the [New] button to create a new sheet for operation posting.

- Enter the following:

- type and number of production order in the Order field,

or

- resource in the Resource field,

or

- operation name in the Operation

- Operations possible to be posted will be displayed in the work pane table according to the selected filter criteria.

- Complete the following editable columns:

- Report date

- Employee

- Reported quantity

- Reported setup time

- Reported processing time

- If the line item is used entirely, select the checkbox in the Completed

- Select [Post operations] button to accept the date.

- Select [Yes] to accept the message displayed in the dialog window