Topic overview

The picking order is a summary of items that are to be provided for another process in the correct quantity and with the correct identifier. It serves as the working basis for the warehouse personnel. At the same time, reporting is used to enable downstream processes. The traceability of identifiers is also based on the reporting.

Possible processes for which picking orders are generated are:

- Production orders

- Delivery orders from external manufacturing orders for material provided to vendor

- Delivery orders from the sales order

- Delivery orders from distribution orders

This article describes for which processes picking orders are generated. The article also lists the relationship between a picking order and other business entities and how it is connected with the business processes.

Definitions of terms

Picking (order)

Picking makes items available, for example, for a delivery to customers or for production. Picking orders include all items that are made available from one warehouse.

Picking order generation

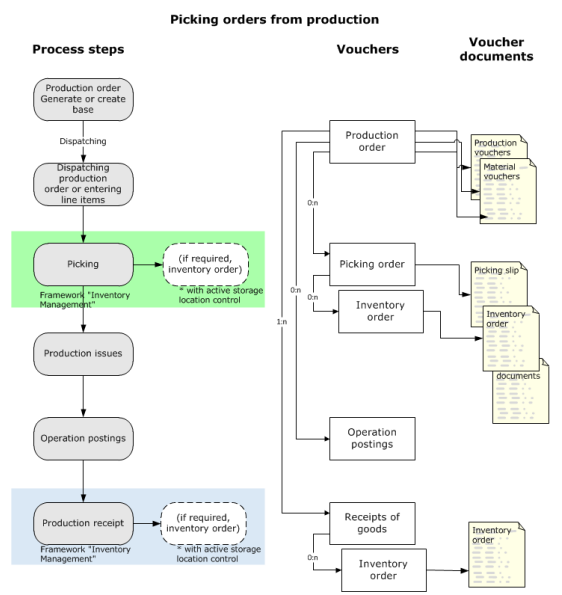

Picking orders from production orders

Picking orders in the production process are needed when items that are necessary for the production are stockpiled at a different warehouse than the production warehouse. In order to provide the material for the production, the [Generate and output picking orders] action is used in the [Production orders] application. It is also available in the production cockpit in the Production orders, base data view. Using the action in the production cockpit, you can also generate a collective picking order for more than one production order at the same time.

Picking orders generated in production orders only have the Picking order view. In this view, reports of quantities are entered or reported by means of the related inventory orders. Inventory orders are generated automatically when the items are to be prepared from a warehouse with storage locations for the production process. If inventory orders could not be created or if inventory orders could be created only for some items, the picking order has one action [Generate inventory orders], with which you can generate inventory orders manually.

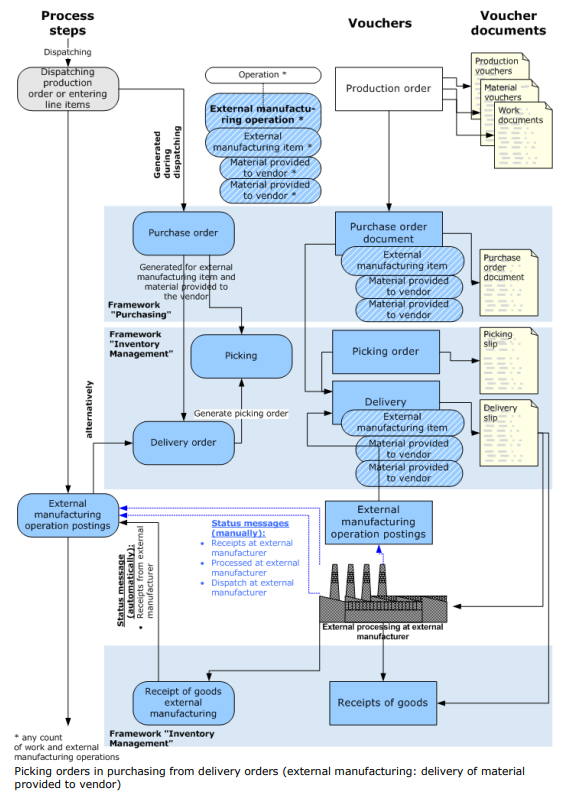

Picking orders in purchasing from delivery orders (external manufacturing)

In the purchasing process, it is possible to generate a picking order only from external manufacturing orders. It serves for preparation of material provided to the vendor. It can be generated as follows:

- Directly from the delivery order that was produced in the course of an external manufacturing through reporting of outside operations, or

- In the Inventory cockpit, in the Delivery orders, base view with the [Generate picking order and output picking slip] action.

Generally, various delivery orders can be summarized in the inventory cockpit as Collective picking orders. Then, the picking order displays the following data for reporting:

- In the Delivery order view, the individual delivery orders with their items or

- In the Picking order view, a version summarized according to items.

When the material provided to the vendor is delivered from a slot-run warehouse, the necessary inventory orders are generated automatically through the picking order. Inventory orders can be also generated automatically with the [Generate inventory order] action in the Picking orders application.

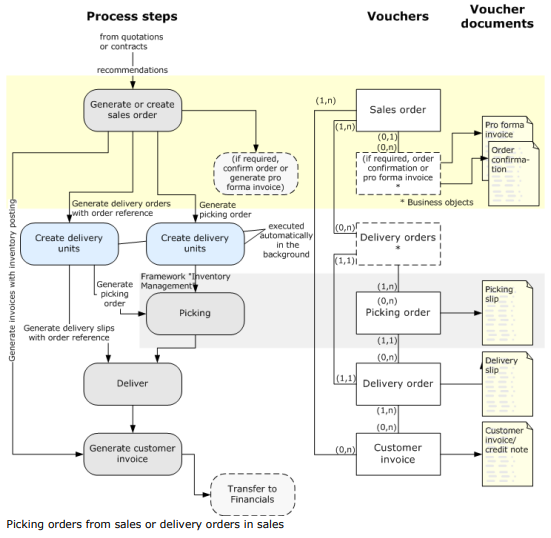

Picking orders in sales from sales orders or delivery orders

Picking orders can be generated with the [Generate and output picking orders] action directly from sales orders. It is necessary, however, that the sales order type contains a picking order type. A delivery order is always generated in the course of picking order generation. Depending on the selected parameter of picking order generation, one or more picking orders are created.

- Multiple picking orders are produced if the parameter per delivery order is selected and the generation from the sales order leads to multiple delivery orders.

For details on the criteria leading to various delivery orders, refer to the Delivery order generation article.

- If the per order parameter is selected, all generated delivery orders, if any, are summarized in the picking order. They are not visible in the Picking orders view, but shown in a per item summary. Reporting can occur through this view.

In the Delivery orders view, items are shown according to their delivery orders with their items. In contrast to the “Picking orders” view, this view offers the option to decide, in case of insufficient quantities of an item, to decide which delivery order is not to be delivered or only partially delivered.

The [Generate and output picking orders] action is also available in the sales cockpit in the Sales orders, base and the Sales orders, items views. In the sales cockpit, picking orders are also created only for sales orders in which a picking order type is entered. First, delivery orders are generated in the sales cockpit. Therefore, in addition to the parameters for picking orders generation, the dialog for this action also contains the parameters for delivery order generation. In the Sales orders, items view, the special features described in the Delivery order generation article apply. If the items of the picking order are to be provided from a slot-run warehouse, reporting occurs through inventory orders that have been generated either automatically or with the [Generate inventory orders] action.

If the sales order does not contain any picking order type, picking orders can be generated in the Delivery orders or the Sales cockpit and the Inventory cockpit applications (the Delivery orders, base view) for delivery orders previously generated from the sales orders.

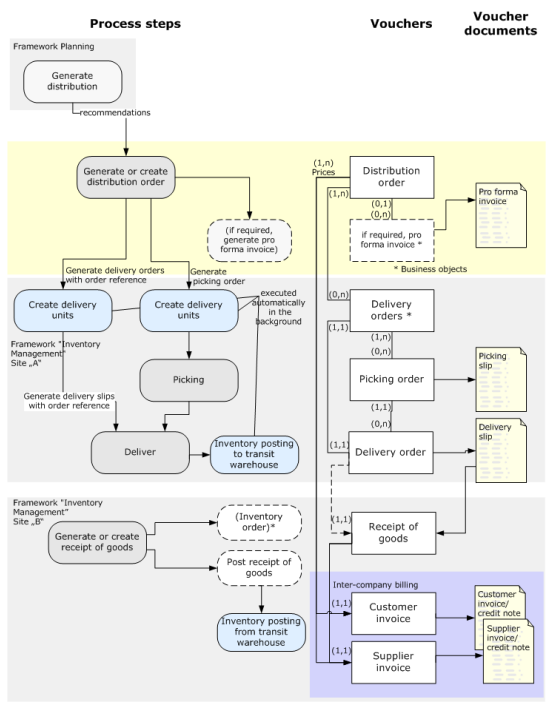

Picking orders from distribution orders or delivery orders

Picking orders from a distribution order can be basically generated only from previously generated delivery orders. For this purpose, the Generate and output picking order application is available in the Delivery orders application and the Delivery orders, base views of the sales and inventory cockpit.

Criteria for collective picking orders

While generating picking orders, it is generally possible to create collective picking orders in the cockpits. The following criteria of upstream vouchers must match for generating collective picking orders:

- Picking order type

- Address of the warehouse

- Location of the warehouse

For summarizing items in a picking order, the following criteria must match:

- Item

- Storage unit

- Main line item yes/no

- Warehouse

- Owner of inventory

- Order unit

Voucher references chain

In the voucher references chain for picking order, the following upstream and downstream vouchers are visible if they are connected through a voucher reference:

Purchase order – the purchase order is displayed in the voucher references chain of the picking order as soon as a picking order is generated from the delivery order that was generated from the purchasing order for external manufacturing.

Production order – the production order is displayed in the voucher references chain if a picking order was generated from the production order in order to provide inventory in the production. In this case, inventory posting is executed through reporting and completion of the picking order, crediting the inventory to the production warehouse.

Sales order – the sales order is displayed in the voucher references chain if a picking order was generated directly from the sales order or if picking order generation was requested from the delivery order that was generated for a sales order.

Distribution order – the distribution order is displayed in the voucher references chain if picking order generation was requested from a delivery order that was generated for a distribution order.

Delivery order – the delivery order is displayed in the voucher references chain if a picking order was generated directly from a sales order or if a picking order was generated from a delivery order. Exception: the picking order for provision of inventory in the production.

Inventory order – the inventory order is displayed in the voucher references chain if am inventory order was generated automatically with generation of the picking order or if an inventory order was created from the picking order with the [Generate inventory order] action.