A picking order voucher is a list of items that warehouse workers are to provide for the delivery process. The Picking Order Types application enables the definition of settings and dependencies for the picking order voucher.

Definitions of terms

Picking (order)

Picking makes items available, for example, for a delivery to customers or for production. Picking orders include all items that are made available from one warehouse.

Picking order type

Picking order types are used to identify picking orders and establish picking default values. With picking order types, the posting keys for production supplies are established and it is specified whether identifiers are assigned automatically.

Application description

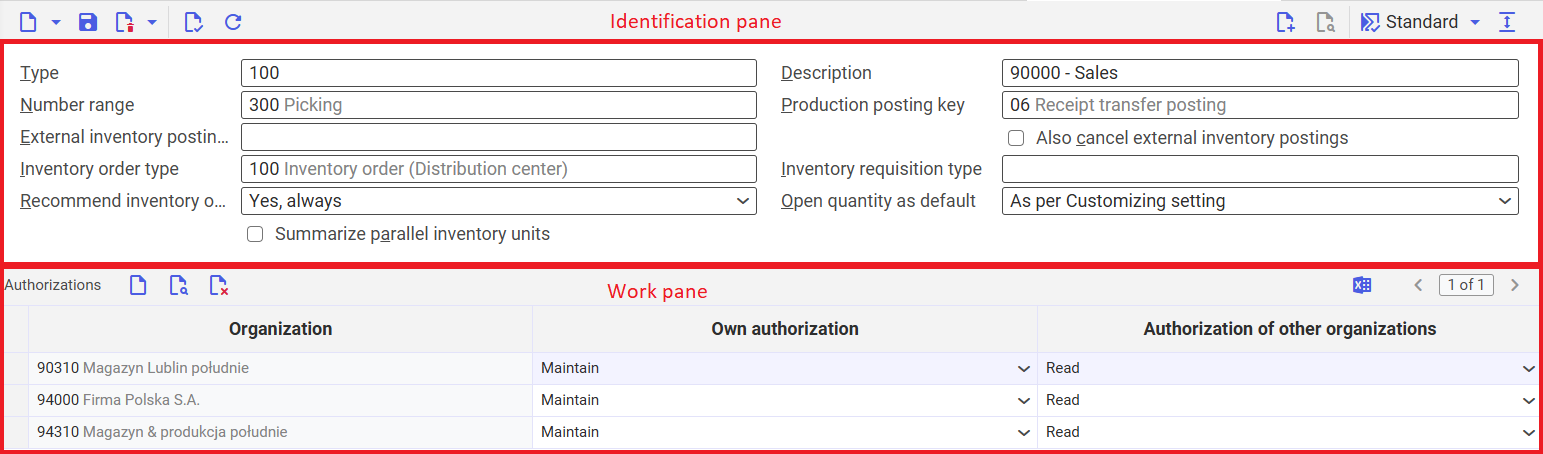

The application consists of:

- Identification pane – containing standard buttons and fields allowing the definition of the basic data for the created picking order type

- Work pane – containing an authorization table for the picking order type, enabling the assignment of specific permissions to internal company organizations

Identification pane

The identification pane of the Picking Order Types application consists of the following fields and parameters:

- Type – allows defining the identifier of the picking order type. A picking order type can be assigned to other voucher types that may require picking, e.g., production order type, sales order type, or delivery order type, to generate a picking order voucher based on them.

- Description – enables the definition of a description for the picking order type

- Number range – allows assigning the number range according to which picking order vouchers of a given type will be numbered

- Production posting key – allows assigning a posting key that defines warehouse processes for picking orders generated from production orders. Picking orders for production require a posting key, as it controls the issue of materials for the production process. The posting key is defined in the Posting keys application. In the Production posting key field, a posting key must be assigned. That key executes the process Receipt transfer posting and has the value Main operation defined in the Operation type field.

- External inventory posting key – allows assigning a revaluation posting key used for executing production processes with materials supplied by subcontractors. Using this posting key, upon the completion of the picking order, ownership of goods will be transferred from the external supplier to the company organization. In the External inventory posting key field, a posting key must be assigned that executes the process Receipt revaluation posting. The ownership of goods will be transferred from the supplier to the company organization.

- Also cancel external inventory postings (checkbox) – executing a revaluation posting for external production inventory creates an inventory posting, i.e., transferring material value from one inventory owner to another. If this parameter is active, when a picking order is canceled, the inventory posting for the external inventory transaction will also be canceled.

- Inventory order type – allows selecting the inventory order type that will be generated from the picking order. An inventory order can be generated only for structural warehouses, since it specifies the exact location from which material is to be picked. The field is visible if the following configuration is active: Customizing → Inventory Management function → Storage Location Control.

- Inventory requisition type – allows selecting the inventory requisition type that will be created for inventory orders executing cross-picking processes. For cross-picking, the inventory order will not be generated automatically upon creation of the picking order voucher, as it depends on the value selected in Items → Inventory Management view → General tab → Delivery data section → Picking field. In the Inventory requisition type field, a requisition with the value Picking issue (defined in the Usage field in the Inventory requisition types application) must be assigned.

- Recommend inventory owner and identifiers – allows defining whether, during the picking process, the system should propose data for voucher items if the picking order is generated from a sales order or production order and not all required data is specified. The system may suggest the following data in the item table:

- Inventory owner – the system proposes the inventory owner for the order item

- Identifiers – the system proposes the identifiers of the goods to be sent to the customer

- Logistic unit – the system proposes the logistic unit in which the goods will be shipped to the customer

Available options:

- Yes, always

- Only in unstructured warehouses

- No

- Open quantity as default – allows defining whether the system will automatically propose open quantities for items in the created picking order type. Available values:

- According to Customizing setting

- Do not use defaults

- Always use default

- Use defaults when picked quantity empty

- Summarize additional item units (checkbox) – if the parameter is active, it is allowed to combine several logistic units for one picking order item. Use of this function is recommended only in exceptional cases, as using several units in one item does not allow automatic picking. It may result in delivery surplus and block remaining quantities for delivery.

Work Pane – Authorization Table

The authorization table in the Picking Order Types application enables assigning authorizations to organizations for using a given picking order type. Organization data and authorization levels are added in a table containing the following buttons and columns:

- [Add] – allows adding authorizations in the table

- [Find and add organization] – opens a dialog window enabling the search and addition of one or more organizations to the table

- [Set/Remove deletion marker] – allows adding or removing a deletion marker for a row in the table. The entry will be deleted after saving the picking order type.

- Organization – allows defining the organization to which authorizations are assigned

- Own authorization – allows selecting authorizations for the defined organization. Available options:

- Read – authorization limited to reading the picking order type only. An organization with read rights cannot edit vouchers.

- Maintain – the defined organization may use the given picking order type

- Authorization of other organizations – allows defining authorizations for other organizations. Available options:

- Read – authorization limited to reading the picking order type only. An organization with read rights cannot edit vouchers.

- Maintain – other organizations may use the given picking order type

Customizing

For the Picking order types application, no settings are to be defined in the Customizing application.

Business Units

For the Picking Order Types application, the relevant business unit is: com.cisag.app.sales.obj.PickingOrderType. It is used, among others, for:

- Assigning authorizations

- Setting activity definitions

- Importing or exporting data

The business unit is part of the following business unit group: com.cisag.app.inventory.OrderData.

Authorizations

Authorizations can be assigned using the authorization roles as well as by assigning an organization. The authorization concept can be found in the technical article Authorizations.

Special capabilities

There are no special capabilities for the Picking order types application.

Organization assignments

If the Content-related authorizations function is activated in the Customizing application, the Picking order types application is only displayed to a person if they have been assigned an organization in the partner master data that is integrated into at least one of the following organizational structures:

- Inventory management

The Picking order types application includes the Authorizations table. In order for a person to use a picking order type, they must be assigned to at least one organization in the partner master data that is entered in the Authorizations table of the picking order type.

Special features

There are no special features for the Picking order types application.

Authorizations for business partners

The Picking order types application is not released for business partners.