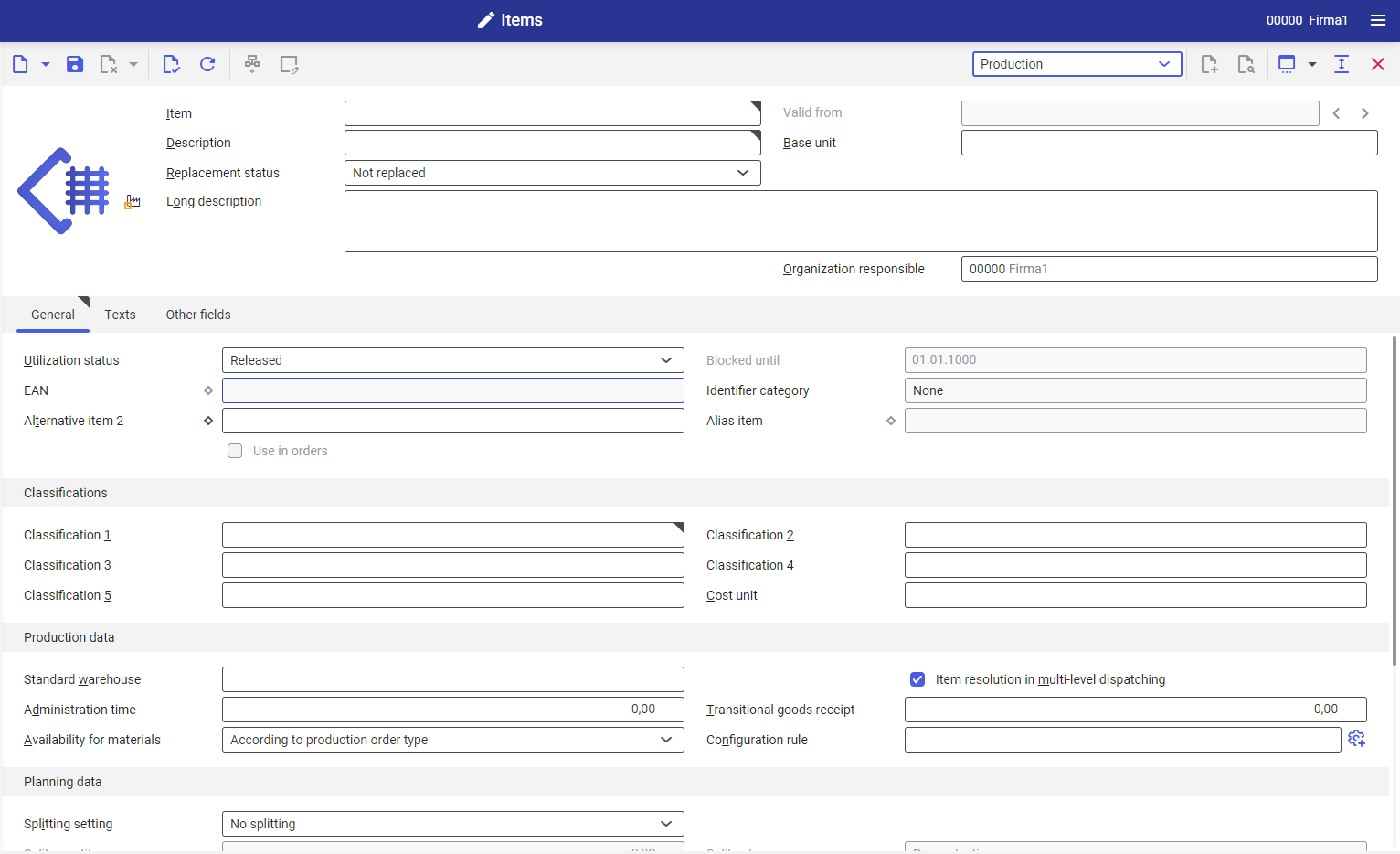

This document describes the procedures for handling the Production view in Items application. The procedures contain instructional steps for creating production data, for instance. Other actions, e.g., creating new item through duplication, is described in documentProcedures: Items.

Add production item data

Preconditions

In a multi-site or single-site environment with activated Content-based authorizations, the selected organization must be a production organization. Furthermore, only the users assigned to the organization responsible for the item can generate new utilizations of an item

In the Production view, it is not possible to create:

- Alias items, since only data in the Base view is created for them

- Items of Service, Billing item and External manufacturing

- Kit items, since only individual components are produced

- Pseudo items

Instructions

- Open the Items application and switch to Production view.

- Click on [New] button on the standard button bar

- Select item category for which production data is to be entered

- If required, change the utilization status of the production item in the General section. It is possible to select Release or Blocked status

- Define required fields:

Classification 1 – enter Production method for the item, depending on the value selected in the Category field, in the Production method

Bill of material – specify Production method for item in accordance with the value selected in the Category field of the Production method

- If necessary, specify y the other item production data.

- Click [Save] on the standard button

Delete production item data

Production item data are not deleted directly and must first be marked for deletion. Only those versions of production items that have their entire validity period in the future can be deleted directly, since they have not been used yet.

Mark a production item for deletion

Preconditions

Production item has not been marked for deletion yet.

Instructions

- Open the Items application.

- Switch to the Production view.

- Open the production item to be marked for deletion.

- In a multi-site environment, select the organization for which you are editing the item.

- Click on [Mark for deletion] in the standard toolbar.

Item production data will be marked for deletion and saved.

Unmark a production item for deletion

Preconditions

Production item data has been marked for deletion.

Instructions

- Open the Items application.

- Switch to Production view.

- Open the production item to be unmarked for deletion.

- In a multi-site environment, select the organization for which you are editing the item.

- Click on [Unmark for deletion] in the standard toolbar.

Deletion marker is removed.

Delete production item data version

Preconditions

A production item version, that will be valid only in the future, exists

Instructions

- Open the Items application.

- Switch to Production view.

- Open the production item for which the version is to be deleted.

- In a multi-site environment, select the organization for which you are editing the item.

- Using Next and Back buttons browse in the Valid from field and switch to a future version of the production item to be deleted.

- Click on the [Delete] button on the standard toolbar.

Selected production item data version will be deleted.

Create a new production item version

Preconditions

In order to generate a new version, it is important for the item to have production data. In Production view, you can generate a new version for items of following material types:

- Inventory item

- Storage units

- Variant items

Instructions

- Open the Items application.

- Switch to Production view.

- In a multi-site environment, select the organization for which the action is to be performed.

- Open the production item for which the future production data version is to be added.

- Click on [New version] button on the standard toolbar.

- Enter a future date from which the production item will be valid in the Valid from field.

- Click the [Save] button in the standard toolbar.

The new version will be saved.

Change utilization status of a production item

Preconditions

You can change the utilization status of a production item by either releasing or blocking it.

Instructions

- Open the Items application.

- Switch to the Production view.

- In a multi-site environment, select the organization for which you are editing the item.

- Open the production item to be edited.

- Change the value of the Utilization status field to Released or Blocked.

- In case of a block, enter a future date, until which the production item cannot be used, in the Blocked until field.

- Click on the [Save] button in the standard toolbar.

The item status will be saved.

Standard production item configuration.

You can save a standard configuration for a production item.

Add production item configuration

Preconditions

In a multi-site environment, the selected organization should have accepted the data processing for production data.

Instructions

- Open the Items application.

- Switch to the Production view.

- Open the production item for which the standard configuration is to be entered.

- In a multi-site environment, select the organization for which you are editing the item.

- Enter a valid configuration rule in the corresponding field.

- Click on the button [Create item configuration] next to the field. A dialog window will be opened.

- In the configuration for dialog window fields, select values which should be specified as standard configuration for the item.

- Click on [Accept] button in the dialog window.

- Click on the [Save] button in the standard toolbar.

The new configuration will be saved.

Change production item configuration

Preconditions

In a multi-site environment, the selected organization should have accepted the data processing for production data.

Instructions

- Open the Items application.

- Switch to the Production view.

- Open the production item for which the standard configuration is to be changed.

- In a multi-site environment, select the organization for which you are editing the item

- Make any changes you need to the configuration rule in the corresponding field.

- Click on the button [Create item configuration] next to the field. A dialog window will be opened.

- In the configuration for dialog window fields, select values which should be changed for the standard configuration for the item.

- Click on [Accept] button in the dialog window.

- Click on the [Save] button in the standard toolbar.

The item configuration will be changed.

Alternate methods

You can save alternate production method for the production item in Alternate methods section.

Add alternate method

Precondition

In a multi-site environment, the selected organization should have accepted the data processing for production data.

Instructions

- Open the Items application.

- Switch to the Production view.

- Open the production item for which the alternate production method is to be entered.

- In a multi-site environment, select the organization for which you are editing the item

- Click on [New] button in the Alternate methods section.

- After clicking on the [New] button, new row appears in the table, where it is possible to specify values for the alternate production method.

- Click on the [Save] button on the standard toolbar.

The alternate production method will be saved.

Delete alternate production method

Preconditions

In a multi-site environment, the selected organization should have accepted the data processing for production data.

Instructions

- Open the Items application.

- Switch to the Production view.

- Open the production item for which the alternate production method is to be deleted

- In a multi-site environment, select the organization for which you are editing the item.

- Select the row of the method you wish to delete in the Alternate production methods section.

- Click on [Delete] button in the Alternate production method section

- Click on the [Save] button on the standard toolbar.

The alternate production method will be deleted.

Accept production item data for a selected organization

Preconditions

This functionality exists only in a multi-site environment or if Content-based authorizations are activated in a single-site environment.

Instructions

- Open the Items application.

- Switch to the Production view.

- Open the item for which you want to accept production data.

- Select the organization for which you want to accept the production data.

- Click on [Accept data for the selected organization] on the standard toolbar.

- Click on the [Save] button on the standard toolbar.

The production data will be accepted for the selected organization.

Accept data processing for a selected organization

Instructions

- Open the Items application.

- Switch to the Production view.

- Open the item for which you want to accept production item data processing.

- Select the organization for which you want to accept the production item data processing.

- Click on [Accept data processing for the selected organization] on the standard toolbar.

- Click on the [Save] button on the standard toolbar.

Production data processing will be accepted for the selected organization.