The basis of the production process is the dependency between planned production stages in time. Time dependencies may be defined for the line items of operations (i.e. resources) and routings (i.e. operations). Such dependencies are taken into account when initiating production orders (in production order reservations) and when planning the production process.

Time dependencies are defined on the Dependencies tab of the line item editor displayed for the following line items:

- resources or resource lists in the Operations application

- operations or routings in the Routings application

- operations and resources in the Production orders application

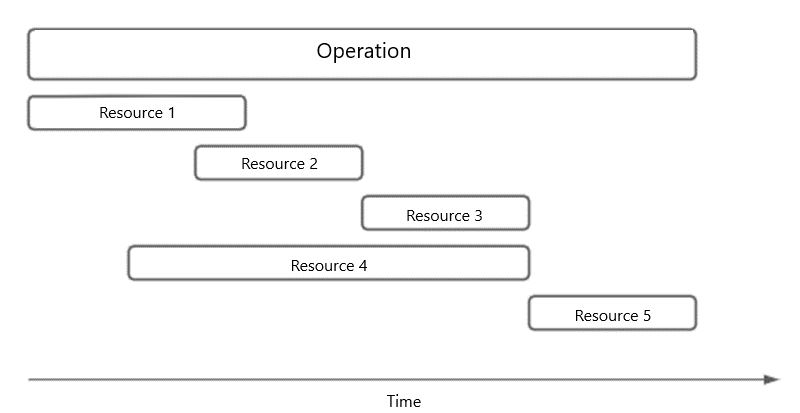

Example of dependencies between operation line items

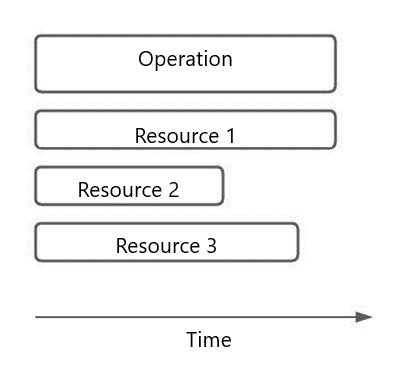

If no dependencies are specified in an operation, resources are scheduled in parallel so that they have the same begin time – see the example in the figure below.

When relevant dependencies are introduced, it is possible to plan operation resources:

In this case, the total operation time results from the processing time of the assigned resources.

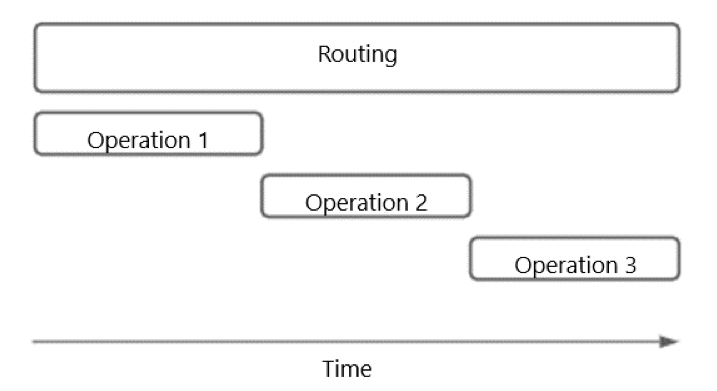

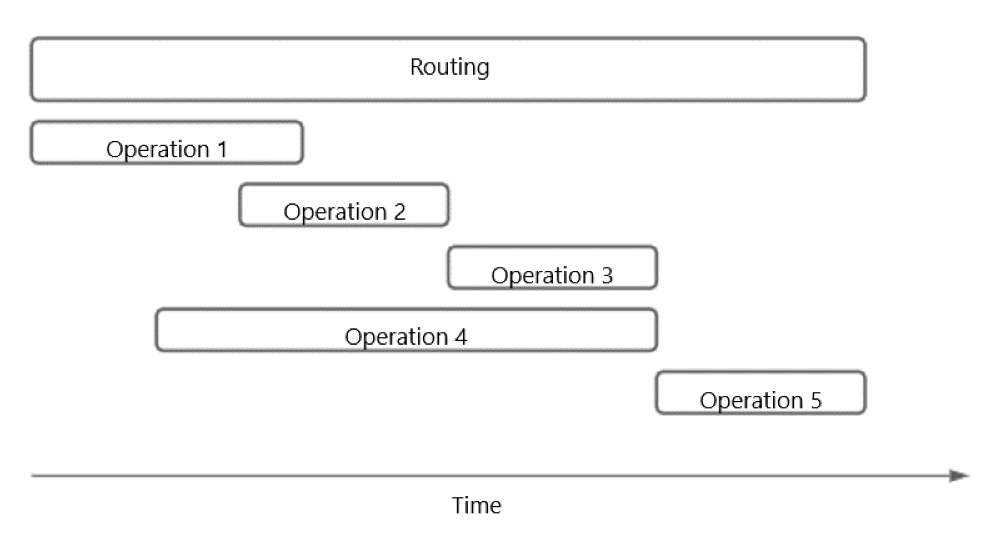

Example of dependencies between routing line items

If there are no dependencies, all routing line items are planned when initiating a production order so that they are executed one after the other, as shown in the figure below.

When relevant dependencies are introduced, it is possible to plan routing operations as follows:

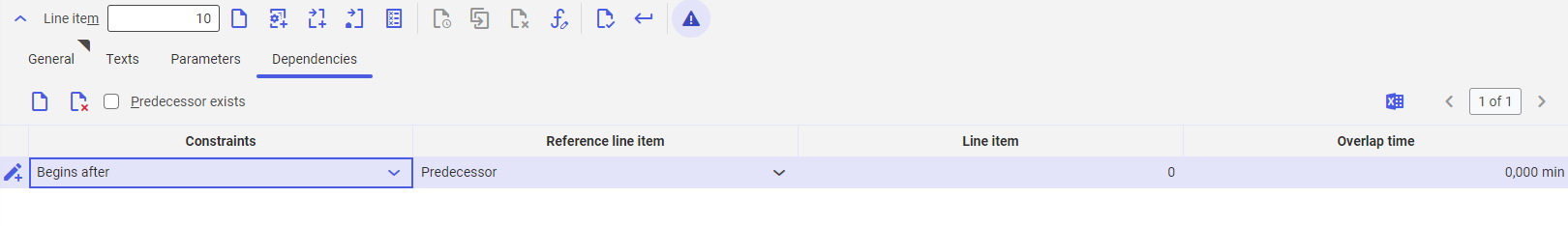

Dependencies tab

The tab makes it possible to associate line items assigned to an operation/routing/production order with each other. The tab contains the following buttons:

- [New] – it defines a new line item dependency and adds a new row in the table below

- [Delete] – it deletes a defined line item dependency

- Predecessor exists – it blocks a resource/operation from starting without completing the preceding resource/operation. It cannot be selected for the first line item.

The table is composed of the following columns:

- Constraints – it makes it possible to define an association between line items; available options include:

- Begins no earlier than

- Begins after

- Begins parallel to

- Ends parallel to

- Ends no later than

- Begins overlapping with

- Reference line item

- Line item – it allows defining the number of a table line item to which a given constrain is to refer to, e.g. Begins no earlier than line item no. 10

- Predecessor – such a dependency always refers to the previous table line item, e.g. Line item no. 20 begins no earlier than the predecessor (line item no. 10)

- Line item – it defines the number of a line item to which a dependency is to refer. The column is only active if the option Line item has been selected in the Reference line item

- Line item number – the detailed number of a line item to which a given dependency refers. The column is only used if an operation has more than one resource. In such a case, resources are numbered in an appropriate manner. The column is only available in the Production orders

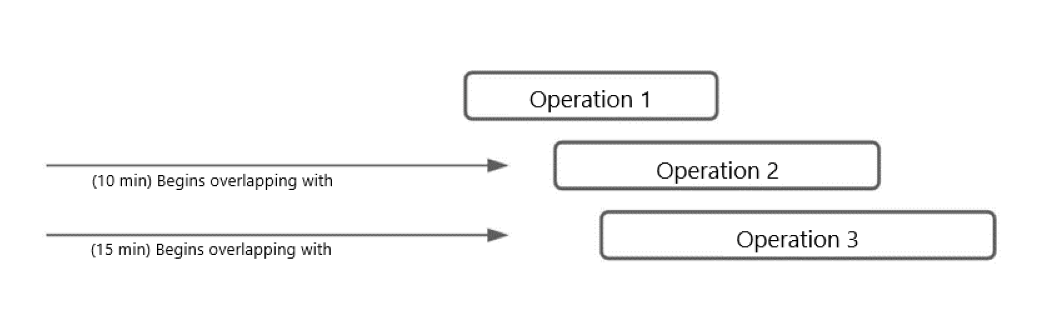

- Overlap time – it determines the maximum overlap time between table line items. The column is only active if the option Begins overlapping with option has been selected in the Constraints

Dependency types

The following chapter presents dependency types using the example of a routing. It is assumed that the Predecessor exists parameter is inactive for operation line items. Moreover, buffer and transport times are not defined. Otherwise, these times would be invalidated by the defined dependencies.

Begins no earlier than

Begins no earlier than means that a given operation cannot begin earlier than one or more selected operations. In the case of a predecessor it is determined automatically, so selecting this dependency type makes sense only in reference to a subsequent line item. The same can be achieved by positioning in the routing.

Begins after

Begins after means that a given operation always begins after one or more preceding operations or after a specified line item. It is possible to enforce such behavior by selecting the parameter Predecessor exists.

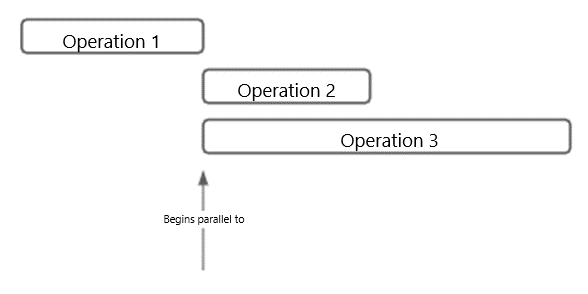

Begins parallel to

Begins parallel to means that a given operation begins at once with one or more different operations.

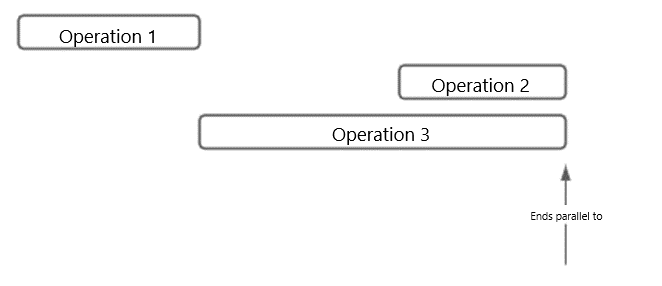

Ends parallel to

Ends parallel to means that a given operation ends at once with one or more different operations. In this case, there is no alternative. This dependency type is used if, for instance, two operations are to be finished simultaneously, so that the next operation can be started immediately afterwards.

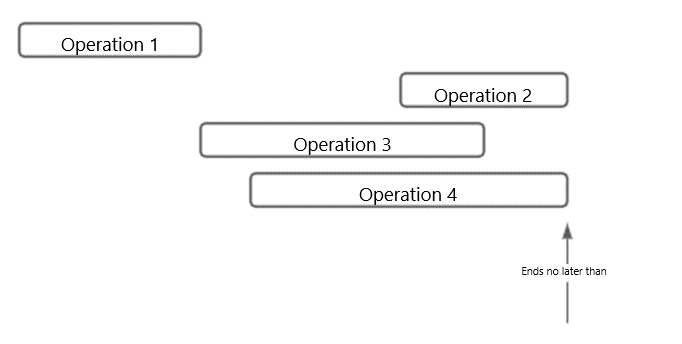

Ends no later than

Ends no later than means that a given operation cannot end later than a selected operation line item. It does not mean that it needs to end at the same moment. Therefore, the earliest possible time is set for line items. It may lead to the overlapping of operations.

Begins overlapping with

This dependency is always used if a given operation should begin before another operation ends. In the case of this dependency type, it is necessary to enter a value in the Overlap time column.

Validation

It needs to be remembered that the system performs the validation of newly created dependencies, verifying whether basic logical dependencies are defined appropriately. In the case of complex routings and operations, the system may not display a logical error. An additional parameter not validated when adding a dependency is operation duration. If a dependency cannot be handled because of operation times and limiting dependency calls, an error occurs when a production order is initiated.

Below is an example of an illogically formulated dependency that could not be handled:

It is possible to formulate a logically correct dependency that could not be handled because of processing times calculated only at the start of a production order.