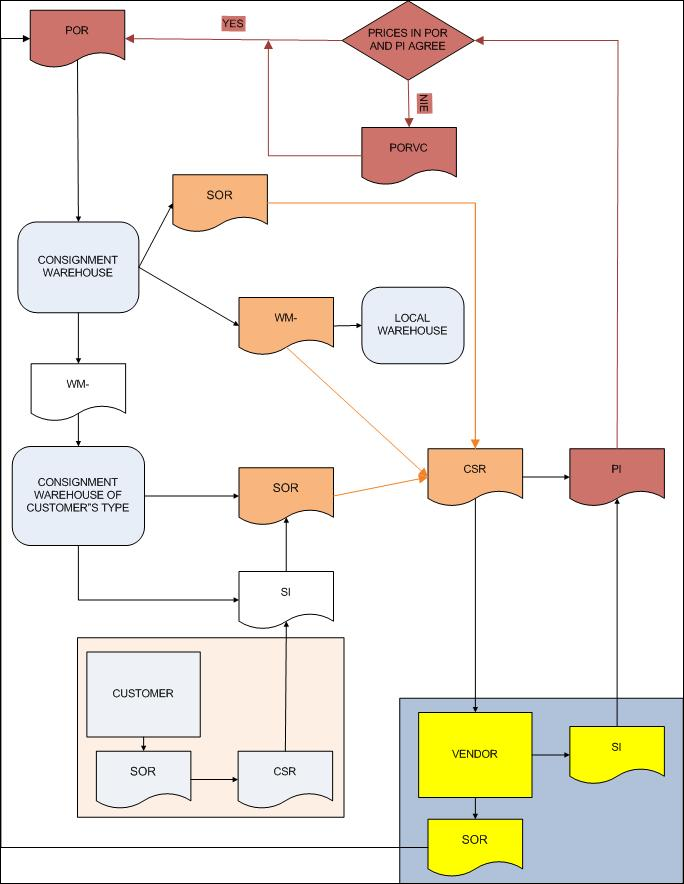

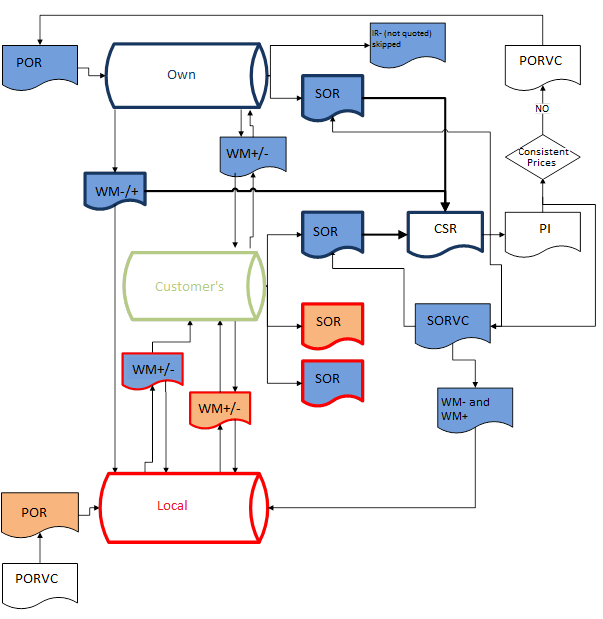

Consignment sales report is used for collecting the whole sale of the resources received from one customer/vendor in one consignment warehouse of Own type in a given period. At the same time, the CSR serves as information for the vendor which items supplied by it have been sold by the customer.

The consignment sales report includes:

- sale of items from delivery from a specific customer/vendor to a consignment warehouse of Own type on the basis of SOR documents.

- “sales” for the customer, whereby the item is moved from the consignment warehouse by means of WM documents to a local warehouse of the customer, thereby becoming their property

- sale of consignment items made by the secondary customers from the consignment warehouse of the secondary customer (documented by a SOR issued to a customer assigned to the consignment warehouse of the secondary customer)

A list of CSR documents and the associated functionality are available in module Sales. The list displays information regarding:

- document number

- date of issue

- code

- secondary vendor name

- warehouse in which an item has been received

- range of dates in which SOR and WM- included in the CSR have been issued

- subtotal and total values of the report

- current document status

The form is composed of the following tabs: General, Attributes, Associated Documents and Attachments

The tab General presents:

- document number

- vendor for whom the report is being created

- warehouse in which the resource delivered by a given vendor has been received (it can only and exclusively be an own consignment warehouse)

- center in which a document is issued

- field with a space for an additional description to a report

- current document status

- date of issue of a document

- subtotal and total values of the report

- range of dates within which the dates of issue of documents including in the created CSR fall

In field Warehouse a warehouse, for which in the configuration the CSR document has been set as default, is set as default. That does not mean, however, that it cannot be replaced with another own consignment warehouse.

Note

It is not possible to issue a CSR to a consignment warehouse of a secondary customer or a local warehouse.

A list of CSR items displays the items and their quantity which has been released within the selected period of time by means of SOR and WM- documents from own consignment warehouse that is the basis of the report.

These items can only be added after selecting a vendor as well as a warehouse. From a list filtered by dates, vendor and warehouse, a user can select specific SOR or/and WM- documents. The other option involves the automatic addition of all SOR and WM- documents fulfilling the criteria set – button [Add Automatically].

Note

In databases with FIFO/LIFO methods selected, the system does not include the documents which have already been added to another CSR (confirmed and unconfirmed), SOR documents which have been completely corrected, and WM- documents associated with a SORQC.

Note

In databases with AVCO method selected, upon adding a WM- document to a CSR, it is possible to decrease the quantity. Such WM- document can be added to another CSR document with quantity decreased by quantities already included in other CSR documents.

Example

1. A WM- document is issued with an own consignment warehouse selected as source warehouse and a customer’s consignment warehouse specified as target warehouse. Item Scarf in quantity 10 pcs is added onto the document.

2. The WM- is confirmed

3. The WM- is included in a CSR document, quantity is automatically transferred from the WM-

4. Quantity of item Scarf is decreased on the CSR from 10 pcs to 8 pcs

5. Another CSR document is issued, the WM- from p. 1. is included in it with quantity 2 pcs (10 pcs from the WM- – 8 pcs included in the first CSR)

Prices of the individual items are retrieved from the current price list for received items assigned to the vendor selected in the CSR, in system currency of a company being the document owner. They are not editable and are only used for information purposes. They can differ from the prices in the POR and PI, which ultimately document the purchase.

A CSR document can also be generated from the list of SOR and WM- documents. Generation can be performed for one or many documents checked in the list. With regard to WM-, these can be documenting whose source warehouse is own consignment warehouse and whose target warehouse is a local warehouse. Documents are generated with Unconfirmed status.

After confirming the CSR document, it is sent to the vendor who in return submits a sales invoice that includes exactly the same items. After receiving such an invoice, an operator can generate a corresponding purchase invoice from the CSR list level.