The pack monitor is a tool enabling the user to quickly find information on the current status of a given pack, track the pack’s history, or generate appropriate documents for packs.

The pack monitor may be accessed in the following menus:

- Purchase → Pack Monitor

- Warehouse → Pack Monitor

Both the lists present the same data.

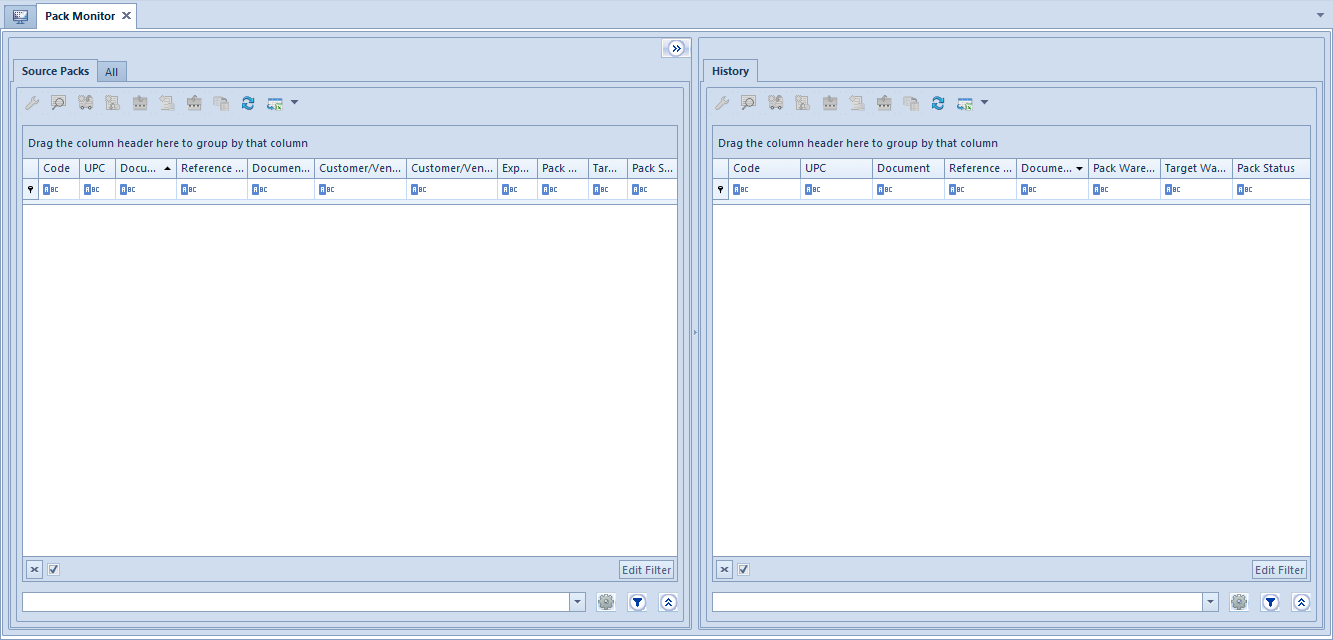

Pack monitor form

The pack monitor form is divided into two sections:

- The first one is composed of the tabs Source Packs and All

- The second one contains the tab History

Source Packs tab

The tab presents the list of packs sorted by a document date; to be displayed, a pack needs to meet the following conditions:

- It cannot be created on the basis of other packs

- The status of a document to which a given pack belongs is other than Canceled

- The operator has been granted a permission for previewing a document to which a given pack belongs

The list of source packs is composed of the following columns:

- Code

- UPC

- Document – it displays the number of a document to which a given pack belongs

- Reference Number – the number is retrieved from a pack’s document (it applies to PO, POR, and PI documents)

- Document Date (PO, IR+, WM- – date of issue; POR, PI – date of receipt)

- Customer/Vendor Code and Customer/Vendor Name – they are retrieved from a pack’s main document (it applies to PO, POR, PI, and IR+ documents)

- Expected Date – it displays a pack’s expected date (applies to PO documents)

- Pack Warehouse

- Target Warehouse – it displays the name of a warehouse to which a given pack is to be sent (applies to WM- documents)

- Pack Status – it displays the status of the last pack associated with a source pack displayed on the list

All tab

This tab’s layout is analogous to the one on the Source Packs tab. The only difference is that the All tab presents all packs registered in the system, and not source packs only. Moreover, the status of each pack refers to a specific pack only, and not to the last pack associated with a given source pack, as on the Source Packs tab.

History tab

The History tab does not need to be displayed. By default, it is hidden – to display the tab, it is necessary to select the arrow icon located in the top right corner of the form.

The pack history section is closely connected with the other section of the form. It presents the history of a pack currently selected on either the tab Source Packs or All, and is dynamically refreshed upon each change of selection.

The system understands pack history as the history of packs directly or indirectly related to a currently selected pack. Historical records are limited to:

- Packs associated with documents with a status different than Canceled

- Packs that can be previewed by the operator – as in the case of the other tabs

Document generation

On the tabs Source Packs and All in the pack monitor window, it is possible to generate documents for selected packs. However, such documents are not always generated directly from a document with which a selected pack is associated, or from the specific pack as well.

Purchase order receipt

During the generation of a POR document, the system chooses one of the two generation types:

- Generation on the basis of unprocessed PO items belonging to a selected pack

- Generation on the basis of “unreceived” PI items associated with a selected pack

When determining the list of packs for which a POR document is to be generated, the system verifies whether:

- A PO document has the status Confirmed or Pending

- There is no non-deducted and uncanceled advance invoice related to the PO document

- A PI document has the status Confirmed or Posted

- A warehouse specified for a given pack is assigned to the POR document definition in a center in which the generation process takes place

If all the abovementioned conditions are met, the system generates a POR document.

Purchase invoice

Generating a purchase invoice document also involves two generation types, as in the case of POR generation. The difference between the two generation processes performed in the pack monitor window is that while generating a purchase invoice, the system searches for “non-invoiced” POR items instead of “unreceived” PI items. Additionally, the system verifies the status of a POR document, instead of a PI document.

Warehouse movements

The generation of a WM- document in the pack monitor window aims to move a given pack to another warehouse. In order to make it possible, a relevant item must be received to a warehouse before. Therefore, if the operator selects a source pack originating from a PO document, the WM- generation process will only be available for such a pack if an associated POR document has been generated before, receiving the pack’s resources to a warehouse.

The generation of a WM+ document allows the user to receive items from packs to another warehouse. The system does not handle the generation of partial WM+ documents from WM- documents, so WM+ documents are always generated in relation to entire WM- documents. In order to maintain the rule of working on single packs, the user should accept the generation of separate WM- documents for packs.