Receiving and delivery reports

Issuing a Receiving and delivery report (RDR) allows for registering what item was actually received in a target warehouse and in what condition When moving an item between warehouses of a given company , it may happen that there is a different item registered in a warehouse movement document than the one which was physically received in a target warehouse or an item delivered to a target warehouse is damaged.

A list of RDR documents is available from the level of Warehouse Reports and provides information about:

- RDR document number

- its date of issue

- number of WM- document to which an RDR document refers

- number of WM+ document which was generated upon confirming an RDR document

- code and UPC number of a pack to which an RDR document was generated (only such an RDR document was generated directly to a pack, not to the whole WM- document)

- discrepancy report number

- current RDR document status

From the level of the list, an operator can confirm, edit, delete or cancel a previously generated RDR document, but cannot add a new one. An RDR document can be generated from a WM- document.

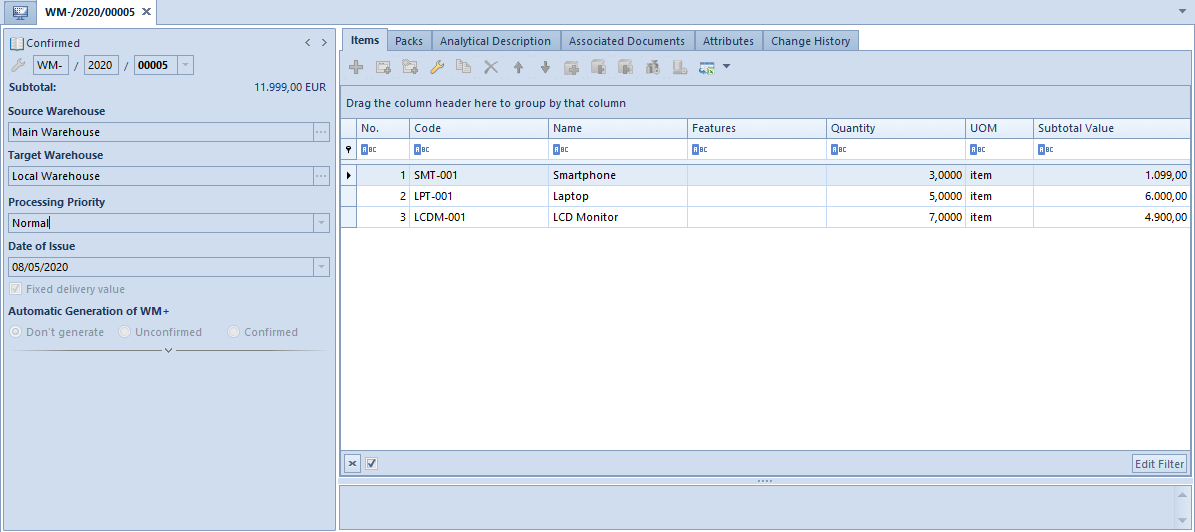

Generating an RDR

An RDR is generated for all items of a WM- document which are not included in any pack or to a single pack from a WM- document.

Options regarding generation of an RDR are available from the level of:

- list of WM- documents – an RDR for items of a WM- document not included in any pack

- details of a WM – document, tab Items – an RDR for items of a WM- document not included in any pack

- details of a WM – document, tab Packs – an RDR for a selected pack from a WM- document

- pack monitor – an RDR for a selected pack from a WM- document

If an unconfirmed receiving and delivery report is already associated with a source WM-, then the system opens this report form in the edit mode.

In case a WM- document to which an RDR is generated is already associated with a WM+ document (and this document is not canceled), the system associates the generated RDR with this WM+.

An RDR document:

- can be generated in a center to which belongs the target warehouse from the WM- document

- is based on permissions to warehouses determined for WM+ document type No warehouses are assigned to RDR document type in its configuration.

- allows for adding an item of a Merchandise or Set type which on item form has parameter Retrieve items onto document checked and does not contain an element of Service type. Upon adding such set, its elements are displayed on the list of items without information that they are contained in a set.

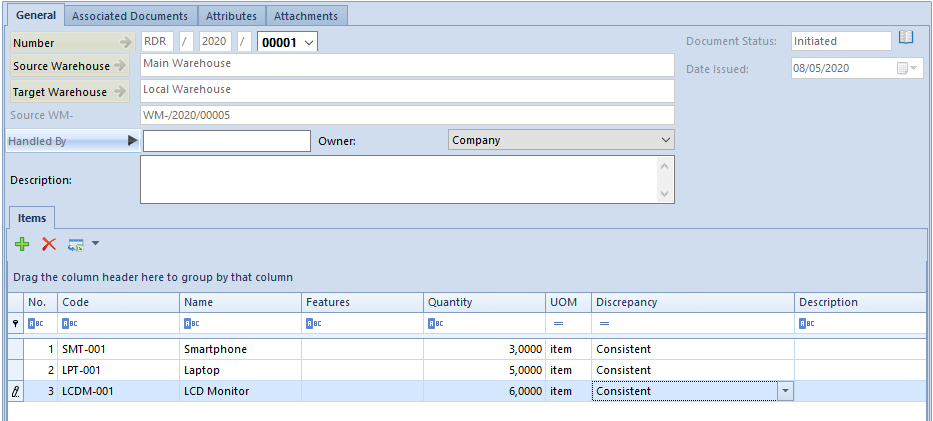

RDR form

RDR form is composed of several tabs – General, Associated Documents, Attributes, Change History and Attachments.

The tab General is composed of:

- RDR document number

- source warehouse from which an item was released – uploaded from a source WM- document, not editable

- target warehouse in which an item is to be received – uploaded from a source WM- document, not editable

- number of a source WM- document to which an RDR refers – determined on the basis of WM- document for which RDR generation was started, not editable

- code and UPC of a pack to which an RDR was generated (visible only if an RDR was generated to a pack) – determined on the basis of data from the pack on WM- document for which RDR generation was started, not editable

- center in which an RDR is issued – by default, it is a center to which an operator issuing an RDR is logged in, however, until a document is confirmed, it is possible to change the center to the one to which operator group including the logged in operator is assigned

- document status

- date of issue – RDR generation date, not editable

- section for additional description

- list of items which were actually delivered to a target warehouse – the list is empty, by default; it is possible to add items which were received in a delivery, specify discrepancy and add its detailed description

Adding an item to RDR

List of RDR items displays data on:

- ordinal number

- item code and name

- features of a given item lot

- quantity of received item lot expressed in basic unit

- type of discrepancy and its description – a user can select a discrepancy type from a dropdown list. The list is retrieved on the basis of generic directory Discrepancy Codes which is available in Configuration General) (Generic Directories) General group of directories.

- When creating a database, four types of discrepancy codes are created, but only one of them – Consistent – is available in an RDR document. It means that an item being received is of standard value. The other three discrepancy codes are used only in discrepancy report in case if an item is missing in a WM- document/pack, whereas it is registered in an RDR, and the other way around. An operator is able to add his own discrepancy codes to the generic directory and use them when issuing RDR documents.

- description

Adding an item to an RDR document is performed with the use of button [Add]. In the item list, the system creates a new row, in which, in column Code, an operator can:

- load an item/lot code with a barcode scanner

- type an item/lot code on a keyboard

- select item from the list of items opened upon clicking on the three-dot symbol, which is available in the column

Barcode scanners and adding items to an RDR

The system enables to configure cooperation with scanners in two ways – to require manual entering of quantity before another item is added or to automatically set the quantity of such item to 1 and create subsequent row upon uploading a code with the use of scanner.

In order to determine the manner of using barcode scanners, check parameter Barcode scanner handling in RDR document definition in a given center and select one of the options: without quantity or with quantity.

Option without quantity means that an operator uses only a scanner and each code is read separately. RDR document will include as many items as many times the operator uploaded a code with the use of scanner. The system will not aggregate the same elements to one item – for each uploaded code, the quantity will be set to 1, by default. It will be possible to change quantity of individual items.

Option with quantity means that an operator will read a code with the use of scanner, but quantity will be specified each time manually. Upon specifying the quantity, the operator must click [Enter] or [Add] for a new row to be added to an RDR and in the added row it will be possible to upload another code.

Confirming an RDR

After adding to a receiving and delivery report all items which have been physically delivered to the target warehouse, the document can be confirmed.

Confirming an RDR results in verifying whether a given RDR is the only or the last RDR that can be created for a given WM- document. The number of RDR that can be created for a WM- depends on whether in the WM- there are any packs and whether there are items not assigned to any pack from the WM-.

If a WM-

- does not contain packs – it is possible to generate only one RDR document and it will refer to the entire WM- document

- contains packs and all items from that WM- are associated with a pack – it is possible to generate as many RDR as the number of packs in the WM-; one RDR for one pack

- contains packs but not all items from that WM- are associated with a pack – it is possible to generate as many RDR as the number of packs (one RDR to one pack) and another one RDR to the items not associated with any pack.

In case a given RDR is the only/the last RDR that can be created to a given WM- document, after confirming that RDR, the system:

- generates a confirmed WM+ to the whole WM- document, but only if no WM+ has yet been generated to that WM-

- generates a DR which includes discrepancies between RDR and WM-, if such discrepancies occur

Canceling an RDR

Canceling an RDR might result in simultaneous canceling of a DR associated with the RDR. However, such a situation occurs only if:

- the DR is not associated with any other RDR or

- the DR is associated with other RDR documents, but all those RDR documents have been already canceled

If conditions of simultaneous cancellation of RDR and DR are fulfilled, when canceling the RDR, the system asks whether a user wants to continue the cancellation.